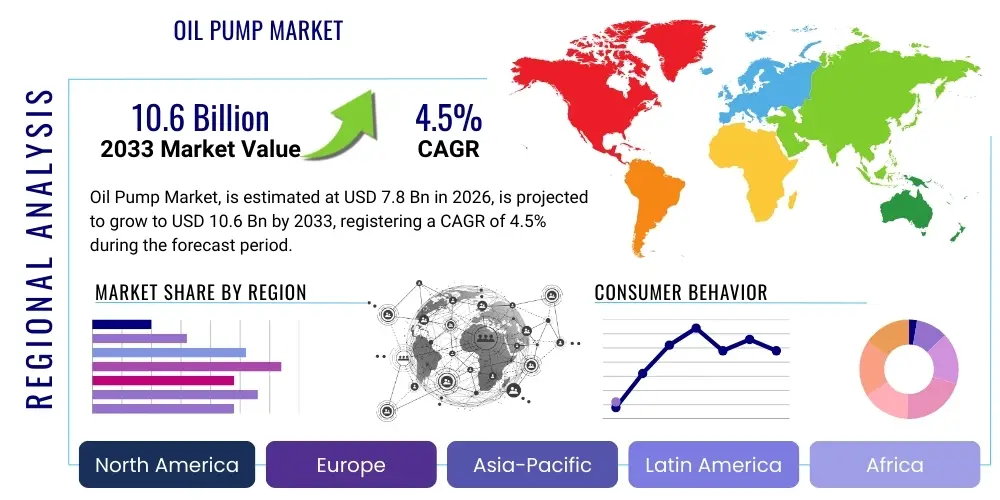

Oil Pump Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436137 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Oil Pump Market Size

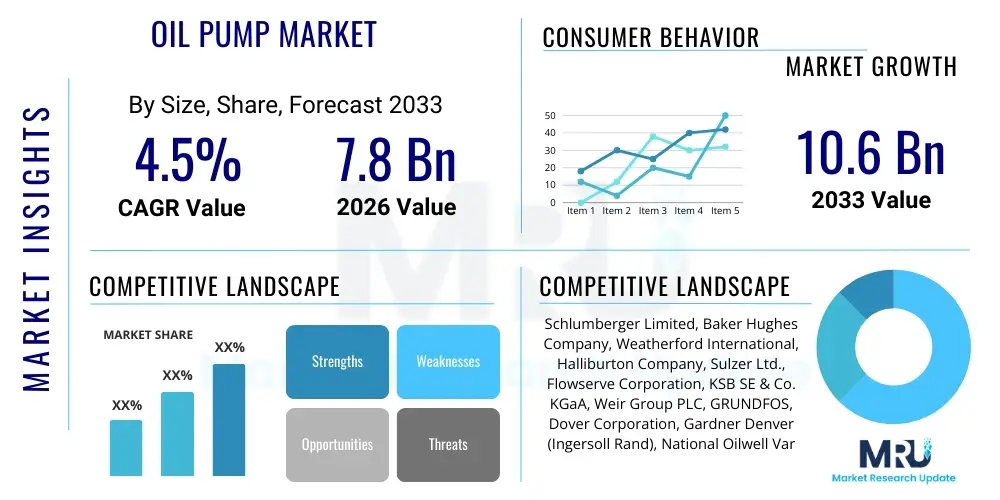

The Oil Pump Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at $7.8 Billion USD in 2026 and is projected to reach $10.6 Billion USD by the end of the forecast period in 2033.

Oil Pump Market introduction

The Oil Pump Market encompasses the manufacturing, distribution, and utilization of mechanical devices crucial for moving crude oil, petroleum products, and natural gas liquids across the energy value chain. These specialized pumps are indispensable in various sectors, including exploration and production (upstream), transportation and storage (midstream), and refining and processing (downstream). Market growth is intrinsically linked to global energy consumption trends, capital expenditure in the oil and gas sector, and the necessity for robust infrastructure capable of operating reliably under high pressure and temperature conditions, often involving corrosive fluids. The primary functions of these pumps include lifting oil from reservoirs, circulating fluids during drilling operations, and transferring processed fuels through pipelines and refineries.

Oil pumps are highly engineered products categorized primarily based on their operating mechanism, such as centrifugal pumps, positive displacement pumps (including reciprocating and rotary types), and specialized submersible pumps used for artificial lift. Key applications span across offshore and onshore drilling rigs, hydraulic fracturing operations, mainline pipeline boosting stations, and critical process units within petrochemical complexes. The continuous demand for reliable fluid handling equipment, coupled with technological advancements aimed at maximizing efficiency and minimizing downtime—especially in mature fields or challenging deep-water environments—underpins the market's trajectory. Furthermore, regulatory mandates concerning environmental safety and leakage prevention drive innovation towards seal-less and magnetic drive pumps, enhancing the overall quality and resilience of deployed machinery.

The core benefit provided by modern oil pumps is the enablement of economical and efficient resource extraction and distribution. Driving factors include the renewed focus on enhancing oil recovery (EOR) techniques, which rely heavily on specialized high-pressure injection pumps, and the ongoing investment in LNG infrastructure globally, requiring cryogenic pumps for gas handling. Although geopolitical instability and the long-term transition towards decarbonization pose certain challenges, the immediate requirement for stable fossil fuel supply chains ensures sustained investment in pump technologies designed for demanding applications and compliance with stringent industry standards like API specifications, thereby ensuring market relevance and steady expansion throughout the forecast period.

Oil Pump Market Executive Summary

The Oil Pump Market is characterized by moderate but stable growth, driven predominantly by renewed upstream investment, particularly in non-conventional resource extraction such as shale gas and deep-water exploration. Business trends indicate a strong move towards digitalization, where major oilfield service providers are integrating intelligent monitoring systems (IoT sensors and analytics) into pumping units to facilitate predictive maintenance, thereby reducing costly operational interruptions and optimizing energy consumption. The market exhibits intense competition, leading manufacturers to prioritize product durability, compliance with increasingly strict emissions standards, and offering comprehensive aftermarket services. Furthermore, supply chain resilience has become a critical strategic focus following recent global disruptions, prompting regional diversification in manufacturing and stocking of key components.

Regionally, the market is spearheaded by North America, attributed to the intensive activity in the Permian Basin and sustained investment in hydraulic fracturing which necessitates specialized high-pressure pumps. The Middle East and Africa (MEA) region also remains a core market, fueled by large-scale national oil company projects focused on expanding production capacity and upgrading aging infrastructure to maintain output stability. Asia Pacific (APAC) is emerging as a significant growth engine, largely due to rapid industrialization, increasing demand for refined products, and new offshore developments in countries like China, India, and Southeast Asia. Regulatory environments, particularly those enforcing methane leak detection and prevention, are influencing procurement decisions globally, favoring vendors offering hermetically sealed or zero-emission pumping solutions.

Segment trends reveal that the positive displacement pump segment, especially reciprocating pumps, holds a significant share due to their efficiency in high-head, low-flow applications often encountered in enhanced oil recovery and metering services. However, the centrifugal pump segment is expected to show the highest growth rate, primarily driven by large-volume transport requirements in midstream operations and widespread use in refinery processes. From an application standpoint, the upstream sector, encompassing production and drilling, remains the largest consumer, but the downstream sector is gaining momentum due to extensive global refinery modernization projects aimed at processing heavier crude types and meeting cleaner fuel specifications. Strategic acquisitions and collaborations focused on integrating automation and material science expertise are shaping the competitive landscape, emphasizing efficiency and longevity.

AI Impact Analysis on Oil Pump Market

Common user inquiries concerning the impact of Artificial Intelligence (AI) on the Oil Pump Market frequently revolve around how AI can enhance operational uptime, reduce maintenance costs, and improve energy efficiency. Users are keenly interested in predictive maintenance models, asking how algorithms can analyze vibration, temperature, and pressure data in real-time to forecast equipment failure before it occurs, thereby shifting operations from reactive to proactive maintenance schedules. Another prominent area of concern is the potential of AI to optimize pump utilization and sequencing in complex pipeline networks or large well pads, aiming to minimize energy consumption and maximize throughput. Furthermore, queries often address the security implications of connecting pumps to IoT networks and the reliability of AI-driven control systems in mission-critical environments. The underlying expectation is that AI will transform oil pump management from a mechanical maintenance function into a highly efficient, data-driven operational strategy.

The primary influence of AI lies in generating actionable insights from the immense volume of operational data collected from modern pumping units. This shift involves the deployment of machine learning algorithms to detect anomalies that are invisible to traditional monitoring systems. For instance, AI can correlate subtle changes in power draw with fluid viscosity variations or pump degradation, enabling operators to schedule precise, non-invasive maintenance interventions rather than relying on fixed time intervals or catastrophic failures. This predictive capability significantly extends the mean time between failures (MTBF) for expensive pump equipment and minimizes the risk associated with personnel having to enter hazardous operational areas for routine checks. By optimizing variable frequency drive (VFD) settings based on current flow requirements and fluid characteristics, AI also contributes substantially to reducing the overall carbon footprint associated with pumping operations.

Furthermore, AI-driven automation is increasingly being applied to optimize the lift process in upstream production, particularly for Electrical Submersible Pumps (ESPs). Algorithms are used to dynamically adjust pump speed and intake pressure in response to reservoir performance and changing downhole conditions, ensuring the well operates at its maximum potential production curve continuously, which is a key driver for maximizing profitability in mature fields. This move towards intelligent asset management requires substantial upfront investment in specialized sensors, edge computing capabilities, and sophisticated cloud infrastructure, but the long-term returns through reduced operational expenditure (OpEx) and enhanced recovery rates are compelling, solidifying AI as a transformative technology in oil pump deployment and management.

- Implementation of Predictive Maintenance (PdM) using Machine Learning models.

- Real-time optimization of Variable Frequency Drives (VFDs) for peak energy efficiency.

- Automated monitoring of vibration signatures and acoustic anomalies for failure forecasting.

- Enhanced remote control and diagnostic capabilities via secure IoT integration.

- Optimization of Enhanced Oil Recovery (EOR) injection pump parameters based on reservoir simulations.

- Improved supply chain forecasting and inventory management for critical pump components.

- Autonomous adjustment of Electrical Submersible Pump (ESP) operating points to maximize production.

DRO & Impact Forces Of Oil Pump Market

The dynamics of the Oil Pump Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form the Impact Forces determining market trajectory. Key drivers include the sustained global demand for crude oil and refined products, necessitating continuous production and transportation capabilities, coupled with robust infrastructure investments, particularly in deep-water and ultra-deep-water regions where highly specialized, high-reliability pumps are mandatory. Furthermore, the imperative for companies to maximize asset recovery rates drives the adoption of advanced Enhanced Oil Recovery (EOR) techniques, which are pump-intensive, utilizing high-pressure injection pumps for water, chemicals, or CO2. The increasing maturity of conventional oil fields globally requires constant replacement and upgrade of artificial lift systems, providing a steady demand floor for pump manufacturers.

Conversely, the market faces significant restraints, primarily stemming from the volatile nature of crude oil prices, which directly impacts the upstream sector's capital expenditure (CAPEX) budgets; prolonged periods of low oil prices can halt or delay major infrastructure projects, curbing pump procurement. Regulatory pressure related to climate change and emissions targets also restrains growth, as stricter environmental rules necessitate expensive redesigns and investments in pump technologies that prevent leakage and minimize energy consumption, increasing the initial acquisition cost. Moreover, the long-term global shift towards renewable energy sources and the electrification of transportation pose a structural constraint, signaling a potential slowdown in demand for fossil fuel-related infrastructure in the distant future, influencing long-term investment decisions by market players.

Opportunities in the market center around technological innovation, specifically the development of smart pumps integrated with Industrial IoT (IIoT) for enhanced monitoring and automation, facilitating true predictive maintenance and remote operation in hazardous environments. The rising demand for specialized pumps capable of handling non-conventional resources, such as high-viscosity bitumen and abrasive oil sands, presents a niche growth area requiring advanced materials science and design. Furthermore, growth in the midstream sector, driven by pipeline expansion projects globally, particularly in areas connecting production hubs to refining centers, creates continuous demand for large, high-capacity mainline centrifugal pumps. These forces collectively dictate competitive strategies, emphasizing efficiency, digitization, and material durability as core requirements for market success.

Segmentation Analysis

The Oil Pump Market is systematically segmented across various dimensions, including pump type, application, operating structure, and regional geography, allowing for precise market evaluation and strategic planning. Segmentation by pump type—which includes centrifugal, positive displacement (reciprocating and rotary), and submersible categories—reflects the mechanical differences required for varying flow rates, pressures, and fluid properties encountered throughout the oil and gas value chain. Application segmentation highlights the primary end-use environments: Upstream (drilling and extraction), Midstream (transport and storage), and Downstream (refining and petrochemicals), with the upstream segment typically dominating due to the necessity of artificial lift systems. Analysis across these segments is crucial for manufacturers to align their product portfolios with specific industry needs and operational requirements.

Segmentation by operating structure further distinguishes between surface pumps, which are easily accessible and used extensively in pipeline boosting and refinery processes, and downhole pumps, such as Electrical Submersible Pumps (ESPs) and rod pumps, which are critical for oil production lift from deep wells. The distinction between these structural types is vital as it dictates maintenance procedures, component design, and installation complexity, directly impacting total cost of ownership (TCO). For instance, downhole pumps require extreme robustness to withstand harsh conditions and minimize the frequency of costly workovers, driving specialized material science research and development.

The detailed segmentation breakdown provides a framework for understanding market maturity and growth potential within specific verticals. While traditional centrifugal pumps maintain volume dominance in midstream and downstream sectors due to high-flow capabilities, the rising complexity of unconventional resources drives disproportionate growth in the positive displacement pump sector, favored for their accurate metering capabilities and high-pressure output essential for hydraulic fracturing and chemical injection in EOR. Regional segmentation remains critical, showing high procurement rates concentrated in regions with intense exploration activities, such as North America and the Middle East, while nascent markets in Africa and Asia-Pacific focus on foundational infrastructure development.

- By Pump Type:

- Centrifugal Pumps (Single Stage, Multi Stage, Axial Flow, Mixed Flow)

- Positive Displacement Pumps (Reciprocating Pumps: Piston, Plunger, Diaphragm; Rotary Pumps: Screw, Gear, Lobe, Vane)

- Submersible Pumps (Electrical Submersible Pumps - ESPs)

- By Application:

- Upstream (Drilling, Artificial Lift, Well Stimulation)

- Midstream (Pipeline Transportation, Storage Tank Transfer)

- Downstream (Refining, Petrochemicals, Processing)

- By Pumping Mechanism:

- Artificial Lift (Rod Pumps, ESPs, Gas Lift)

- Surface Transfer (Pipeline Boosting, Refinery Process Pumps)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Oil Pump Market

The value chain for the Oil Pump Market is segmented into raw material sourcing, component manufacturing, pump assembly and testing, distribution and sales, and critically, post-sales services and maintenance. The upstream segment of the value chain involves sourcing specialized materials such as high-grade corrosion-resistant alloys, stainless steel, and advanced composites required to withstand the abrasive, corrosive, and high-temperature environments typical in oil and gas operations. Key suppliers of these materials, alongside specialized component manufacturers providing seals, bearings, impellers, and sophisticated control systems (VFDs and sensors), define the initial cost and quality benchmarks. Integration of high-tolerance machining capabilities and adherence to stringent industry specifications (e.g., API 610 for centrifugal pumps) are crucial elements at this stage, dictating the overall reliability and longevity of the final product.

The midstream process involves the complex assembly, stringent quality assurance testing, and certification of the complete pumping units. Leading Original Equipment Manufacturers (OEMs) operate highly specialized facilities where advanced hydraulic design principles are implemented to ensure maximum efficiency across varying operating envelopes. Distribution channels are typically complex, utilizing a combination of direct sales for large, customized capital projects—especially in the upstream and midstream sectors—and indirect channels through regional distributors and specialized system integrators for standardized or smaller replacement pumps. Direct channels allow for better client management and customized engineering solutions, while indirect channels provide essential market reach and localized support, particularly in emerging markets where complex logistics are prevalent.

The downstream activities involve installation, commissioning, and comprehensive aftermarket support, which represents a significant portion of the total market value and profitability for pump manufacturers. Post-sales services, including spare parts supply, predictive maintenance contracts, and equipment refurbishment, are essential for maximizing the operational lifespan of the pumps, especially given the critical nature of their application in preventing costly shutdowns. This service-intensive phase focuses heavily on rapid response times and the availability of expert technical personnel, often requiring the deployment of sophisticated digital twins and remote monitoring tools to ensure operational continuity. Success in the downstream market segment is contingent upon establishing reliable, widespread service networks and leveraging data analytics for proactive customer engagement.

Oil Pump Market Potential Customers

The potential customer base for the Oil Pump Market is extensive, spanning the entire hydrocarbon extraction, processing, and transportation ecosystem. The largest segment of end-users are Exploration and Production (E&P) companies, including both international oil companies (IOCs) such as ExxonMobil and Shell, and national oil companies (NOCs) like Saudi Aramco and CNPC. These entities are the primary purchasers of artificial lift systems (ESPs, rod pumps) and specialized drilling circulation pumps, driven by the need to maintain or increase crude oil output from existing and new reservoirs. Their buying decisions are heavily influenced by the pump's reliability, efficiency (power consumption), and compliance with strict safety and environmental standards, particularly for deep-water and harsh environment operations.

Midstream operators, comprising pipeline transmission companies and storage facility owners, form the second major customer cohort. These entities require large-scale, high-flow centrifugal pumps for mainline boosting stations and specialized positive displacement pumps for metering and transfer operations at terminals and tank farms. Reliability and minimizing downtime are paramount for midstream customers, as failures can lead to widespread supply chain interruptions. Procurement cycles in the midstream sector are often tied to major infrastructure projects, making long-term strategic partnerships and proven equipment track records highly valued during the vendor selection process. Furthermore, the increasing complexity of fluid mixtures necessitates pumps designed with advanced sealing technology to prevent leakage and minimize environmental risk.

The downstream sector, encompassing petroleum refineries and petrochemical plants, represents the third major customer group. Refiners purchase a wide array of pumps—including API 610 compliant process pumps, magnetic drive pumps, and metering pumps—used for transferring various intermediate and finished products, handling corrosive chemicals, and circulating cooling water. Demand in this sector is driven by modernization projects aimed at improving processing efficiency, adapting to varying crude feedstock types, and adhering to strict quality specifications for fuels (e.g., low sulfur content). Service providers and engineering, procurement, and construction (EPC) firms also act as crucial intermediaries and buyers, often purchasing pumps as part of broader turnkey solutions delivered to the end-user clients in all three sectors (Upstream, Midstream, Downstream).

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $7.8 Billion USD |

| Market Forecast in 2033 | $10.6 Billion USD |

| Growth Rate | CAGR 4.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schlumberger Limited, Baker Hughes Company, Weatherford International, Halliburton Company, Sulzer Ltd., Flowserve Corporation, KSB SE & Co. KGaA, Weir Group PLC, GRUNDFOS, Dover Corporation, Gardner Denver (Ingersoll Rand), National Oilwell Varco (NOV), ITT Inc., SPX Flow, Ebara Corporation, Roper Technologies, CNOOC, Viking Pump, Pentair plc, Xylem Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Oil Pump Market Key Technology Landscape

The technological landscape of the Oil Pump Market is rapidly evolving, driven by the demand for increased efficiency, reduced operational expenditure, and enhanced environmental compliance. A core focus is on developing advanced materials technology, particularly specialized coatings and exotic metal alloys (e.g., Duplex and Super Duplex Stainless Steels, Titanium alloys), designed to provide superior resistance to highly corrosive media, high levels of hydrogen sulfide (H2S), carbon dioxide (CO2), and abrasive solids often encountered in non-conventional oil and gas production environments. This material innovation is essential for extending the operational life of critical components like impellers and seals, thereby reducing the frequency of costly maintenance and improving the Mean Time Between Failures (MTBF). Furthermore, advancements in hydraulic design utilize Computational Fluid Dynamics (CFD) modeling to optimize pump internals, ensuring that units operate closer to their Best Efficiency Point (BEP) across a wider range of operating conditions, which is crucial for maximizing throughput in fluctuating reservoir environments.

Digitalization represents the most transformative technology currently impacting the market. The integration of Industrial Internet of Things (IIoT) sensors, advanced telemetry systems, and variable frequency drives (VFDs) into pumping units allows for real-time performance monitoring and sophisticated condition-based maintenance strategies. Smart pumps communicate crucial data such as vibration analysis, bearing temperature, flow rates, and pressure transients to centralized control systems and cloud platforms. This data stream, when processed by AI and machine learning algorithms, enables the generation of precise failure predictions, allowing operators to transition from reactive or time-based maintenance schedules to truly predictive regimes. This technological shift not only drastically cuts maintenance costs but also significantly minimizes unplanned downtime, which can be devastatingly expensive in high-volume production or refining operations.

Specific technology innovations are highly evident in the artificial lift segment, particularly with Electrical Submersible Pumps (ESPs). Modern ESP systems incorporate highly efficient Permanent Magnet Motors (PMMs) which offer significant energy savings compared to traditional induction motors, a vital consideration given the high power consumption of downhole equipment. Further, modular pump designs are gaining traction, allowing for faster installation and easier field replacement of worn components without pulling the entire assembly out of the wellbore, significantly reducing workover time and costs. The integration of advanced sealing systems, including magnetic couplings and double mechanical seals, is also crucial for meeting stringent environmental regulations by minimizing leakage risk, especially in sensitive ecological areas and offshore installations, reinforcing the industry's commitment to operational safety and environmental stewardship.

Regional Highlights

- North America: North America, particularly the United States, stands as the leading market due to the high volume of onshore unconventional oil and gas activities, including hydraulic fracturing in the Permian Basin, Bakken, and Eagle Ford shales. This necessitates large fleets of specialized high-pressure positive displacement pumps (especially frac pumps) for well stimulation and robust ESPs for production optimization. Canada's oil sands activities also contribute significantly, demanding heavy-duty pumps capable of handling highly abrasive and viscous fluids. The market here is mature, technology-driven, and highly competitive, characterized by rapid adoption of digital solutions and automation to enhance efficiency and reduce labor costs.

- Middle East and Africa (MEA): This region is characterized by extensive conventional oil reserves and major national oil company (NOC) investments focused on capacity expansion and infrastructure modernization. Countries like Saudi Arabia, the UAE, and Kuwait require large, heavy-duty centrifugal pumps for high-volume crude pipeline transportation and sophisticated EOR injection pumps to maintain production levels in aging mega-fields. Africa, particularly Nigeria and Angola, focuses on offshore deep-water projects, driving demand for highly reliable, subsea-qualified pump systems. Long-term stability in demand, driven by strategic national plans, makes MEA a crucial and stable market for OEMs.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by escalating energy demand from rapidly industrializing nations such as China, India, and Indonesia. Growth is concentrated across all segments: upstream activity in offshore fields (South China Sea, Bay of Bengal), significant midstream investments in LNG receiving terminals and domestic pipelines, and massive downstream refinery expansion projects. Local manufacturing capabilities are growing, but demand for high-end, specialized pumps compliant with international API standards is primarily met by global leaders.

- Europe: The European market, primarily centered around the North Sea (Norway, UK), is mature and focused on maximizing recovery from existing, older fields and decommissioning activities. Demand for new pumps is lower than in growth regions, but high-specification pumps for subsea tiebacks, environmental compliance, and specialized maintenance services are critical. Eastern Europe and Russia maintain steady demand related to pipeline transport and localized production activities, emphasizing cold-weather performance and robust materials technology.

- Latin America (LATAM): LATAM's market dynamics are heavily influenced by the offshore pre-salt developments in Brazil, which require highly complex deep-water pumping solutions. Mexico's energy reforms and renewed investment in state-owned oil infrastructure also contribute to demand. Challenges such as economic volatility and political instability can influence project timelines, but the long-term potential in major resource countries remains substantial, driving demand for both standard surface and complex subsea pump configurations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Oil Pump Market.- Schlumberger Limited

- Baker Hughes Company

- Weatherford International

- Halliburton Company

- Sulzer Ltd.

- Flowserve Corporation

- KSB SE & Co. KGaA

- Weir Group PLC

- GRUNDFOS

- Dover Corporation

- Gardner Denver (Ingersoll Rand)

- National Oilwell Varco (NOV)

- ITT Inc.

- SPX Flow

- Ebara Corporation

- Roper Technologies

- CNOOC (through subsidiary pump manufacturers)

- Viking Pump

- Pentair plc

- Xylem Inc.

Frequently Asked Questions

Analyze common user questions about the Oil Pump market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for oil pumps in the upstream sector?

Demand in the upstream sector is primarily driven by global energy consumption requirements, continued investment in complex exploration projects (such as deep-water and unconventional drilling), and the critical need for artificial lift systems (like ESPs) to maximize oil recovery from mature or declining conventional wells, ensuring sustained output.

How is the adoption of IoT and AI influencing the maintenance strategies for oil pumps?

IoT integration enables real-time data collection on pump performance metrics (vibration, temperature, pressure). This data feeds into AI algorithms to facilitate predictive maintenance (PdM), drastically reducing unplanned downtime, optimizing scheduling, and lowering operational costs compared to traditional reactive maintenance models.

Which pump type holds the largest market share in terms of revenue, and why?

Centrifugal pumps generally account for the largest revenue share, predominantly due to their widespread application in high-volume, low-head midstream pipeline boosting operations and their critical roles across various processes within large downstream refineries and petrochemical facilities.

What are the main regional growth opportunities for oil pump manufacturers in the near term?

The most significant growth opportunities are concentrated in the Asia Pacific (APAC) region due to heavy investment in new refinery construction and LNG infrastructure, and the Middle East, driven by National Oil Companies' sustained mega-projects focused on production capacity expansion and sophisticated EOR implementation.

What material advancements are crucial for oil pump resilience in harsh operating environments?

Crucial material advancements include the use of advanced corrosion-resistant alloys, such as Duplex and Super Duplex Stainless Steels, and specialized ceramics and elastomers for sealing components. These materials are essential for resisting the highly corrosive effects of H2S, CO2, and high chloride content found in challenging unconventional or deep-water reservoirs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Electrically Operated Oil Pump Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Electric Oil Pump Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Electric Oil Pump Market Size Report By Type (Separate Pump, Integrated Pump), By Application (Start-Stop System, Electric and Hybrid Vehicle), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager