Polyester Filament Yarn Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440635 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Polyester Filament Yarn Market Size

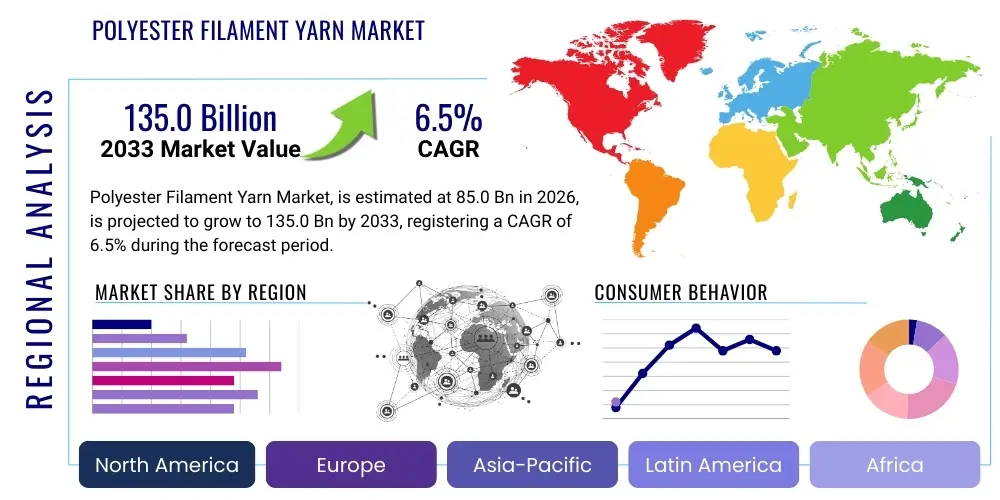

The Polyester Filament Yarn Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 85.0 billion in 2026 and is projected to reach USD 135.0 billion by the end of the forecast period in 2033.

Polyester Filament Yarn Market introduction

Polyester Filament Yarn (PFY) is a synthetic fiber renowned for its exceptional strength, durability, and versatility. Manufactured from polyethylene terephthalate (PET) chips, PFY undergoes a complex spinning and drawing process to produce continuous filaments, which are then either twisted or textured to achieve specific properties. This material forms the backbone of the modern textile industry, offering a superior alternative to natural fibers in numerous applications due to its resilience and cost-effectiveness. The manufacturing process involves polymerization of PTA (purified terephthalic acid) and MEG (monoethylene glycol) to form PET, which is then melted and extruded through spinnerets to create fine filaments. These filaments are subsequently stretched and processed into various forms such as Partially Oriented Yarn (POY), Drawn Textured Yarn (DTY), and Fully Drawn Yarn (FDY), each serving distinct purposes based on their characteristic strength, luster, and texture.

Major applications for Polyester Filament Yarn span across a wide array of industries, with textiles and apparel being the primary consumers. It is extensively used in the production of clothing, sportswear, activewear, home furnishings like curtains, upholstery, and carpets, as well as in industrial textiles. Its inherent benefits, including high tensile strength, resistance to shrinkage, stretching, and wrinkling, make it ideal for durable and low-maintenance products. PFY also boasts excellent resistance to abrasion, chemicals, and mildew, contributing to the longevity and performance of end products. Its ability to be blended with other fibers further expands its utility, allowing for the creation of fabrics with enhanced properties such as improved drape or breathability.

The market for Polyester Filament Yarn is primarily driven by the burgeoning global textile and apparel industry, fueled by rising disposable incomes, evolving fashion trends, and a growing population. The increasing demand for cost-effective, high-performance fabrics, particularly in emerging economies, significantly propels market expansion. Furthermore, the advancements in textile technology, leading to the development of specialized PFY variants for technical textiles, smart textiles, and sustainable applications, are opening new avenues for growth. The adaptability of PFY to diverse manufacturing processes and its consistent quality also contribute to its widespread adoption across various end-use sectors, ensuring its sustained market relevance.

Polyester Filament Yarn Market Executive Summary

The Polyester Filament Yarn market is experiencing dynamic shifts, influenced by several key business trends. Manufacturers are increasingly focusing on sustainability initiatives, including the development of recycled polyester yarns and more energy-efficient production processes, in response to growing environmental concerns and consumer demand for eco-friendly products. Innovations in yarn technology, such as specialized finishes for moisture-wicking, UV protection, and anti-microbial properties, are expanding PFY's application scope beyond traditional textiles into performance wear and technical fabrics. Strategic collaborations and mergers among key players are also prevalent, aimed at consolidating market share, enhancing production capabilities, and optimizing supply chain efficiencies to meet global demand more effectively. The emphasis on product differentiation through R&D remains a critical aspect for maintaining competitive advantage.

Regionally, Asia Pacific continues to dominate the Polyester Filament Yarn market, driven by its robust textile manufacturing infrastructure, large production capacities, and significant consumer base in countries like China, India, and Southeast Asian nations. This region benefits from lower production costs and strong export potential, making it a global hub for PFY production and consumption. North America and Europe, while mature markets, are seeing growth in high-value, specialized PFY segments, including recycled and performance-oriented yarns, fueled by stringent regulatory standards and a preference for sustainable products. Latin America and the Middle East & Africa are emerging as promising markets, characterized by increasing industrialization, rising disposable incomes, and developing textile industries, attracting investments for new manufacturing facilities and expanding distribution networks.

Segment-wise, Partially Oriented Yarn (POY) remains a dominant segment due to its versatility as an intermediate product for further processing into DTY and FDY. The Drawn Textured Yarn (DTY) segment is witnessing substantial growth, particularly in apparel and home furnishings, owing to its soft feel and natural fiber-like texture. Fully Drawn Yarn (FDY) continues to be essential for applications requiring high strength and smoothness, such as woven fabrics and industrial applications. By application, the apparel sector holds the largest share, driven by fast fashion trends and the increasing adoption of sportswear. However, technical textiles and home furnishings are expected to exhibit significant growth, propelled by innovation and rising consumer spending on durable and aesthetically pleasing products. The market is also seeing a trend towards specialized PFY for automotive, medical, and geotextile applications, highlighting its adaptability.

AI Impact Analysis on Polyester Filament Yarn Market

User inquiries about AI's impact on the Polyester Filament Yarn market frequently revolve around its potential to revolutionize efficiency, sustainability, and product innovation. Common themes include how AI can optimize manufacturing processes, predict market demand, enhance supply chain resilience, and contribute to the development of advanced materials. There's significant interest in AI's role in improving resource utilization, reducing waste, and enabling more precise quality control, addressing both cost-efficiency and environmental concerns. Users also express expectations regarding AI's capability to foster product customization and accelerate the design of new, high-performance PFY variants for specialized applications, ultimately leading to a more agile and responsive market.

The integration of Artificial intelligence (AI) in the Polyester Filament Yarn market is poised to introduce transformative changes across the entire value chain. In manufacturing, AI-driven systems can optimize production parameters such as temperature, pressure, and spinning speed in real-time, leading to reduced energy consumption, minimized material waste, and improved yarn quality consistency. Predictive maintenance algorithms, powered by AI, can anticipate equipment failures, thereby reducing downtime and maintenance costs. Furthermore, machine learning models can analyze vast datasets from production lines to identify subtle defects and anomalies, enabling proactive adjustments and significantly enhancing overall operational efficiency and yield.

Beyond the factory floor, AI holds immense potential for strategic decision-making and market responsiveness. AI tools can analyze complex market data, including consumer trends, economic indicators, and competitor activities, to provide highly accurate demand forecasts. This enables PFY manufacturers to optimize inventory levels, plan production schedules more effectively, and reduce the risk of overproduction or stockouts. In supply chain management, AI can optimize logistics, track raw materials, and predict potential disruptions, ensuring a more resilient and agile supply chain. Moreover, AI can accelerate research and development by simulating material properties and testing new formulations virtually, thereby shortening product development cycles for novel PFY types with enhanced performance characteristics or sustainable profiles.

- Enhanced production efficiency and yield through real-time process optimization.

- Predictive maintenance for manufacturing machinery, reducing downtime and operational costs.

- Improved quality control and defect detection using machine vision and anomaly detection.

- Accurate demand forecasting and inventory management for better market responsiveness.

- Optimized supply chain logistics, risk management, and raw material sourcing.

- Accelerated R&D for new PFY formulations and specialized yarn properties.

- Facilitation of sustainable practices through resource optimization and waste reduction.

- Development of smart textiles and functional PFY with integrated AI capabilities.

- Personalized product development and customization for specific customer needs.

- Data-driven insights for strategic business planning and competitive analysis.

DRO & Impact Forces Of Polyester Filament Yarn Market

The Polyester Filament Yarn market is significantly influenced by a confluence of driving factors, restraints, opportunities, and external impact forces. A primary driver is the robust expansion of the global textile and apparel industry, propelled by increasing disposable incomes, evolving fashion trends, and a growing middle class, particularly in emerging economies. The inherent advantages of PFY, such as its cost-effectiveness, durability, wrinkle resistance, and versatility, make it a preferred choice over natural fibers for a wide range of applications, further stimulating demand. Additionally, technological advancements in yarn manufacturing and processing are continuously leading to the development of higher quality, specialized, and performance-enhanced PFY variants, catering to diverse industrial and technical textile needs.

Despite these drivers, the market faces several restraints. Volatility in the prices of raw materials, primarily crude oil derivatives like PTA (purified terephthalic acid) and MEG (monoethylene glycol), directly impacts production costs and profit margins for PFY manufacturers. Environmental concerns associated with the production and disposal of synthetic fibers, including microplastic pollution and energy intensity, pose significant regulatory and public perception challenges. Competition from natural fibers, though often higher in cost, and the growing demand for sustainable alternatives also act as competitive pressures. The capital-intensive nature of PFY manufacturing, requiring substantial investment in machinery and technology, can also be a barrier to entry for new players and limits rapid capacity adjustments.

However, considerable opportunities exist for market expansion. The increasing demand for technical textiles in sectors such as automotive, medical, sports, and construction presents a lucrative avenue for specialized PFY products designed for high-performance applications. The growing focus on sustainability is driving innovation in recycled polyester filament yarn (rPFY) and bio-based polyester, attracting environmentally conscious consumers and brands. Furthermore, the development of smart textiles incorporating PFY with conductive or sensory properties offers a promising growth frontier. Emerging markets in Asia Pacific, Latin America, and Africa, with their burgeoning textile industries and rising consumer bases, represent untapped potential for market penetration and capacity expansion. The impact forces shaping the market include stringent environmental regulations, shifting consumer preferences towards sustainable and performance-oriented products, geopolitical factors affecting global supply chains, and continuous technological advancements that redefine production capabilities and product attributes.

Segmentation Analysis

The Polyester Filament Yarn market is extensively segmented based on various critical parameters including product type, application, and end-use industry, providing a granular view of its diverse landscape. This segmentation allows for a deeper understanding of market dynamics, consumer preferences, and growth opportunities within specific niches. Product type segmentation typically differentiates between various forms of PFY such as Partially Oriented Yarn (POY), Fully Drawn Yarn (FDY), Drawn Textured Yarn (DTY), and Air Textured Yarn (ATY), each possessing distinct characteristics and processing requirements that cater to different manufacturing processes and end-product specifications. This categorization is crucial for manufacturers to tailor their production lines and offerings to meet specific demand patterns across the global market. Furthermore, the market also considers segmentation by denier count and luster (e.g., bright, semi-dull, full-dull) to cater to the aesthetic and functional needs of textile producers.

Application-based segmentation delineates the primary uses of PFY in various products. The apparel sector, covering everything from everyday clothing to high-performance sportswear, remains the largest application segment, driven by its versatility and cost-effectiveness. Home furnishings, encompassing upholstery, curtains, carpets, and bedding, constitute another significant application, benefiting from PFY's durability and ease of maintenance. The industrial sector utilizes PFY for geotextiles, conveyor belts, ropes, tire cords, and automotive fabrics, where its high strength and resilience are paramount. Additionally, specialty applications in medical textiles, filtration fabrics, and protective wear are growing rapidly, requiring tailored PFY solutions. Each application segment exhibits unique demand drivers and growth trajectories, making it essential for strategic market analysis.

End-use industry segmentation overlaps significantly with application, but provides a broader perspective on the ultimate consumers or sectors. This includes the textile industry itself, which further processes PFY into fabrics; the apparel manufacturing industry for clothing; the home furnishing industry for interior textiles; and various industrial sectors that integrate PFY into their products for specific functional requirements. Geographical segmentation is also crucial, dividing the market into major regions like North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, as regional economic conditions, consumer preferences, and regulatory environments significantly impact market demand and supply dynamics. This multi-faceted segmentation helps stakeholders identify target markets, develop tailored strategies, and forecast future growth trends with greater precision.

- By Product Type:

- Partially Oriented Yarn (POY)

- Fully Drawn Yarn (FDY)

- Drawn Textured Yarn (DTY)

- Air Textured Yarn (ATY)

- Spin Drawn Yarn (SDY)

- Bright Yarn

- Semi-Dull Yarn

- Full-Dull Yarn

- Recycled Polyester Filament Yarn (rPFY)

- By Application:

- Apparel (Woven, Knitted)

- Home Furnishings (Upholstery, Curtains, Carpets, Bedding)

- Industrial Textiles (Geotextiles, Conveyor Belts, Ropes, Hoses, Seatbelts)

- Automotive Textiles (Car interiors, Seat Covers)

- Sports & Activewear

- Medical & Hygiene Products

- Filtration Fabrics

- Non-Woven Fabrics

- By End-Use Industry:

- Textile Industry

- Apparel Industry

- Home Furnishing Industry

- Automotive Industry

- Construction Industry

- Healthcare Industry

- Sports Industry

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Polyester Filament Yarn Market

The value chain for the Polyester Filament Yarn market is a complex network involving several stages, starting from raw material sourcing and extending to the end-user. Upstream analysis focuses on the procurement of primary petrochemical derivatives essential for PFY production. The key raw materials are Purified Terephthalic Acid (PTA) and Monoethylene Glycol (MEG), which are derived from crude oil. Major suppliers in this segment include large petrochemical companies that produce these intermediates. The cost and availability of these raw materials significantly influence the profitability and operational stability of PFY manufacturers. Therefore, securing stable and cost-effective supply agreements with these upstream suppliers is critical for maintaining competitive pricing and consistent production schedules in the PFY market. Fluctuations in crude oil prices directly impact the cost of PTA and MEG, subsequently affecting the entire value chain.

The midstream segment of the value chain is dominated by Polyester Filament Yarn manufacturers. These companies convert PTA and MEG into PET chips through polymerization, and then further process these chips into various types of PFY (POY, DTY, FDY, ATY) through processes like spinning, drawing, and texturizing. This stage is highly capital-intensive, requiring advanced machinery and sophisticated technological expertise. Manufacturers strive for efficiency, quality control, and product diversification to cater to the varied needs of the downstream textile industry. Strategic investments in R&D to develop specialized yarns, improve manufacturing processes, and enhance sustainability profiles are crucial for these players to maintain a competitive edge and expand their market presence globally. Capacity utilization and technological upgrades are key performance indicators in this segment.

Downstream analysis involves the various industries that utilize PFY as a key input for their products. This includes textile mills that weave or knit PFY into fabrics, apparel manufacturers who transform fabrics into garments, and home furnishing companies that produce items like curtains, upholstery, and carpets. Industrial users also form a significant downstream segment, utilizing PFY for applications such as geotextiles, automotive interiors, and conveyor belts. The distribution channels for PFY are diverse, encompassing both direct and indirect sales. Direct sales often occur between large PFY manufacturers and major textile or apparel groups through long-term contracts. Indirect channels involve a network of distributors, agents, and traders who supply PFY to smaller and medium-sized enterprises (SMEs) in various regional markets. The efficiency and reach of these distribution networks are vital for ensuring timely delivery and broad market penetration, especially across international borders where logistics and customs procedures can add layers of complexity.

Polyester Filament Yarn Market Potential Customers

The Polyester Filament Yarn market serves a broad and diverse range of potential customers, primarily concentrated within the global textile and manufacturing industries. The largest segment of end-users consists of apparel manufacturers, who extensively utilize PFY for producing a wide array of clothing items, including casual wear, formal wear, sportswear, and activewear. The versatility of PFY, offering benefits like durability, wrinkle resistance, and moisture-wicking properties, makes it an ideal choice for fabrics that need to be both functional and aesthetically appealing. As fashion trends continue to evolve and demand for performance apparel grows, these manufacturers represent a consistently significant customer base for various types of PFY, particularly DTY and FDY, which provide different textures and strengths suitable for diverse garment types.

Another substantial customer segment includes home furnishing manufacturers and textile producers specializing in interior applications. This encompasses companies that create upholstery fabrics, curtains, drapes, bedding, carpets, rugs, and other decorative textiles. PFY's resistance to fading, abrasion, and shrinking, combined with its ability to hold color well, makes it highly desirable for products that require longevity and ease of maintenance in a domestic setting. The growing global real estate market and increasing consumer spending on home décor further drive demand from this sector. Additionally, technical textile manufacturers represent a rapidly expanding customer base. These companies produce specialized fabrics for demanding applications in industries such as automotive (seat covers, airbags, headliners), construction (geotextiles, roofing), medical (surgical gowns, bandages), and agriculture (crop covers).

Beyond these major sectors, PFY also finds applications with industrial manufacturers who use it for conveyor belts, ropes, fishing nets, tire cords, and various filtration products due to its high tensile strength and chemical resistance. Companies focused on sports and outdoor equipment, including tents, backpacks, and athletic gear, also form a valuable customer segment, leveraging PFY's lightweight durability. Moreover, the increasing emphasis on sustainability has led to a growing demand from brands and manufacturers committed to eco-friendly practices, specifically seeking recycled polyester filament yarn (rPFY). This broad spectrum of end-users, each with unique requirements for strength, texture, performance, and sustainability, underscores the pervasive utility and market depth of Polyester Filament Yarn, necessitating a diverse product portfolio from manufacturers to cater to these varied customer needs effectively.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85.0 Billion |

| Market Forecast in 2033 | USD 135.0 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Reliance Industries Limited, Indorama Ventures Public Company Limited, Xinfengming Group Co., Ltd., Tongkun Group Co., Ltd., Shenghong Group, Zhejiang Hengyi Group Co., Ltd., Far Eastern New Century Corporation, Formosa Plastics Corporation, DAK Americas LLC, Sinopec Yizheng Chemical Fibre Company Ltd., Bombay Dyeing and Manufacturing Company Limited, Alpek S.A.B. de C.V., PT. Pan Brothers Tbk, TORAY INDUSTRIES, INC., INVISTA, Nanya Plastics Corporation, Jiangsu Sanfangxiang Group Co., Ltd., Fujian Billion Polymer Fiber Co., Ltd., Huvis Corporation, Hyosung TNC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Polyester Filament Yarn Market Key Technology Landscape

The Polyester Filament Yarn (PFY) market is characterized by a dynamic and continuously evolving technology landscape, driven by the imperative to enhance efficiency, reduce costs, improve product quality, and meet increasing demands for sustainable and specialized yarns. Core to PFY production is the continuous polymerization process, where PTA and MEG are reacted to form molten PET, which is then directly fed into spinning lines. This continuous process minimizes energy consumption and improves consistency compared to batch processes. High-speed spinning technologies are crucial, allowing for faster production rates and finer denier yarns, which are essential for lightweight and high-performance fabrics. Innovations in spinneret design and spinning parameters enable the creation of yarns with varied cross-sections and properties, catering to diverse aesthetic and functional requirements.

Further down the production chain, texturizing technologies play a pivotal role in imparting bulk, stretch, and a natural fiber-like feel to the smooth polyester filaments. Draw Texturing (DTY) machines, which combine drawing and twisting processes, are continuously being refined for higher speeds, energy efficiency, and better texturizing effects. Air Jet Texturing (ATY) technology is gaining traction for its ability to produce yarns with a cotton-like feel and appearance, broadening PFY's application in casual wear and home textiles. Advancements in these texturizing processes focus on creating multi-functional yarns with enhanced comfort, drape, and performance characteristics, such as improved moisture management, thermal insulation, and anti-pilling properties. The integration of advanced automation and robotics in these manufacturing steps is also becoming commonplace, optimizing material handling, reducing labor costs, and improving overall operational precision.

Beyond core manufacturing, the technology landscape is heavily influenced by sustainability-driven innovations and the development of smart textiles. Technologies for recycling PET waste into high-quality recycled PFY (rPFY) are rapidly advancing, encompassing both mechanical and chemical recycling methods. These innovations address environmental concerns and meet the growing demand for circular economy solutions. Furthermore, research and development efforts are focused on creating bio-based polyester alternatives, utilizing renewable resources to reduce reliance on petrochemicals. In the realm of smart textiles, PFY manufacturers are exploring techniques to incorporate conductive fibers, sensors, and functional coatings directly into the yarn, enabling the production of fabrics with capabilities such as self-heating, health monitoring, and data transmission. These technological advancements collectively define the competitive edge and future growth trajectory of the Polyester Filament Yarn market, fostering innovation across its entire product portfolio.

Regional Highlights

- Asia Pacific: Dominates the global Polyester Filament Yarn market, driven by large production capacities, robust textile industries, and significant consumer demand in countries like China, India, Vietnam, and Pakistan. The region benefits from competitive manufacturing costs, strong export orientation, and a growing domestic market fueled by rising disposable incomes and rapid urbanization. It is a hub for both mass-produced and increasingly specialized PFY.

- Europe: A mature market characterized by a strong focus on high-performance, sustainable, and innovative PFY. Demand is driven by specialized applications in technical textiles (automotive, medical, protective wear) and a growing preference for recycled and eco-friendly polyester. Strict environmental regulations also push manufacturers towards cleaner production technologies and product development.

- North America: Exhibits a steady demand for PFY, particularly in sportswear, activewear, home furnishings, and industrial applications. The market is influenced by consumer preferences for comfort, durability, and performance. There's a rising trend towards adopting recycled PFY and investing in advanced manufacturing technologies to produce specialty yarns domestically.

- Latin America: An emerging market for Polyester Filament Yarn, experiencing growth due to increasing industrialization, expanding textile and apparel manufacturing bases, and rising consumer spending. Countries like Brazil and Mexico are key players, with a focus on both domestic consumption and exports, gradually increasing their reliance on PFY for various textile applications.

- Middle East & Africa (MEA): Shows significant growth potential, driven by developing textile industries, government initiatives to diversify economies away from oil, and increasing investments in manufacturing infrastructure. The region is witnessing a rise in domestic consumption of textile products and a growing demand for cost-effective and versatile fibers like PFY in apparel and home textiles.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Polyester Filament Yarn Market.- Reliance Industries Limited

- Indorama Ventures Public Company Limited

- Xinfengming Group Co., Ltd.

- Tongkun Group Co., Ltd.

- Shenghong Group

- Zhejiang Hengyi Group Co., Ltd.

- Far Eastern New Century Corporation

- Formosa Plastics Corporation

- DAK Americas LLC

- Sinopec Yizheng Chemical Fibre Company Ltd.

- Bombay Dyeing and Manufacturing Company Limited

- Alpek S.A.B. de C.V.

- PT. Pan Brothers Tbk

- TORAY INDUSTRIES, INC.

- INVISTA

- Nanya Plastics Corporation

- Jiangsu Sanfangxiang Group Co., Ltd.

- Fujian Billion Polymer Fiber Co., Ltd.

- Huvis Corporation

- Hyosung TNC

Frequently Asked Questions

What is Polyester Filament Yarn (PFY)?

Polyester Filament Yarn (PFY) is a synthetic yarn made from polyethylene terephthalate (PET) chips, characterized by its continuous, smooth filaments. It is known for its high strength, durability, wrinkle resistance, and versatility, making it a popular choice in the textile industry for various applications.

What are the primary applications of PFY?

PFY is primarily used in the apparel industry for clothing, sportswear, and activewear. It is also extensively utilized in home furnishings (curtains, upholstery, carpets) and industrial textiles (geotextiles, conveyor belts, automotive fabrics) due to its robust properties.

What are the key drivers for the Polyester Filament Yarn market growth?

Key drivers include the expanding global textile and apparel industry, rising disposable incomes, evolving fashion trends, the cost-effectiveness and performance benefits of PFY over natural fibers, and increasing demand for technical textiles in various industrial sectors.

What are the main challenges facing the PFY market?

The PFY market faces challenges such as volatility in raw material prices (PTA, MEG), environmental concerns related to plastic waste and production processes, competition from natural fibers and sustainable alternatives, and the capital-intensive nature of manufacturing.

How is AI impacting the Polyester Filament Yarn market?

AI is impacting the PFY market by optimizing production processes for efficiency and sustainability, enabling accurate demand forecasting, enhancing supply chain management, and accelerating research and development for new, specialized yarn products. It also aids in quality control and predictive maintenance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Recycled Polyester Filament Yarn Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Polyester Filament Yarn Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Polyester Filament Yarn Market Size Report By Type (Partially Oriented Yarn (POY), Polyester Fully Drawn Yarn (FDY), Polyester Drawn Textured Yarn (DTY), Other), By Application (Apparel, Industrial, Household Textiles, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Polyester Fiber Market Statistics 2025 Analysis By Application (Apparel, Industrial and Consumer Textiles, Household and Institutional Textiles, Carpets and Rugs), By Type (Polyester Staple Fiber (PSF), Polyester Filament Yarn (PFY)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Recycled Polyester Filament Yarn Market Statistics 2025 Analysis By Application (Apparel, Automotive, Construction), By Type (Solid Fiber, Hollow Fiber), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager