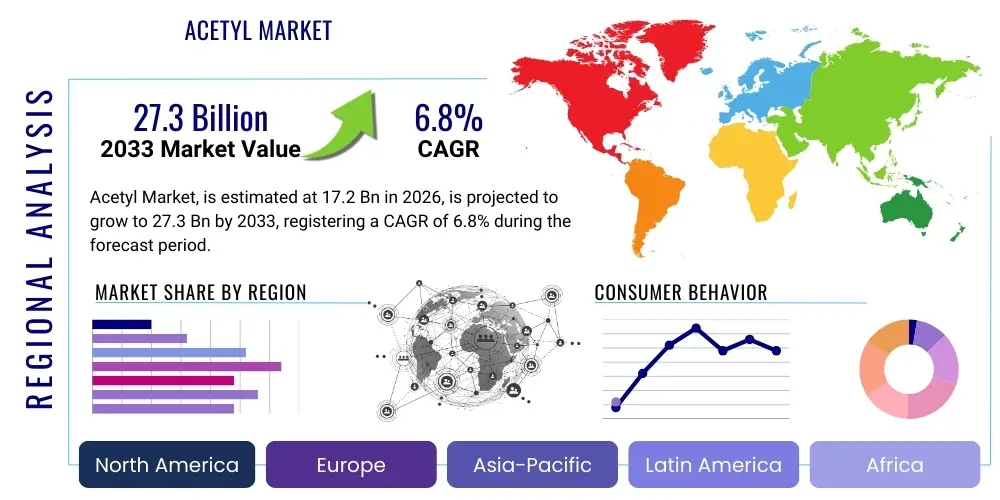

Acetyl Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439400 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Acetyl Market Size

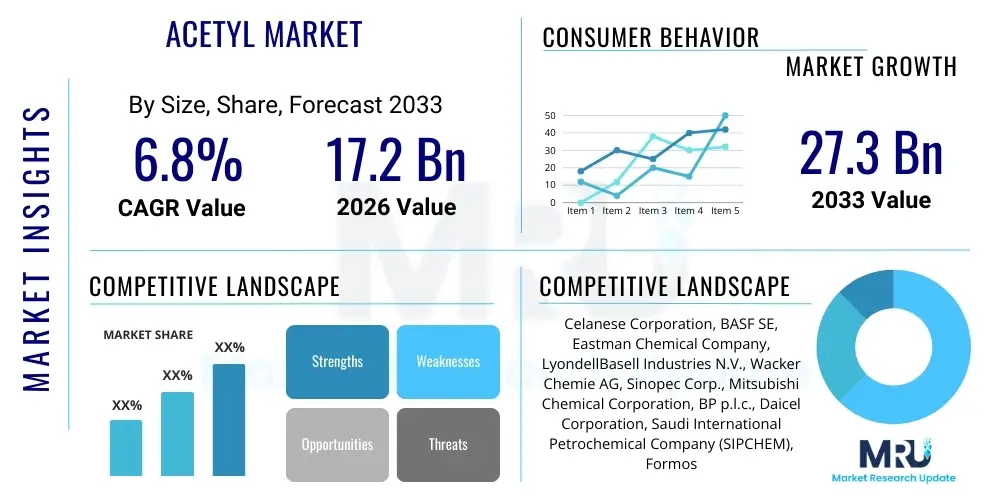

The Acetyl Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 17.2 Billion in 2026 and is projected to reach USD 27.3 Billion by the end of the forecast period in 2033.

Acetyl Market introduction

The Acetyl Market encompasses a broad range of chemical compounds characterized by the presence of an acetyl functional group, with acetic acid serving as the primary building block for many derivatives. These derivatives, including acetic anhydride, vinyl acetate monomer (VAM), ethyl acetate, butyl acetate, and cellulose acetate, are foundational to numerous industrial processes and consumer products. The market's significance stems from the versatility and widespread application of acetyls in diverse sectors globally.

Major applications of acetyl products span across industries such as paints and coatings, adhesives and sealants, textiles, pharmaceuticals, food and beverages, and packaging. For instance, VAM is crucial in the production of polyvinyl acetate (PVA) and ethylene-vinyl acetate (EVA) polymers, extensively used in adhesives and coatings. Cellulose acetate finds application in textile fibers, cigarette filters, and photographic films. The inherent properties of acetyl derivatives, such as their solvent capabilities, polymerizing characteristics, and use as chemical intermediates, contribute significantly to their continued demand across various manufacturing value chains.

The market is primarily driven by the escalating demand from end-use industries, particularly in construction and automotive sectors, which rely heavily on acetyl-based products for coatings, adhesives, and engineering plastics. Additionally, the growing population and rising disposable incomes in emerging economies fuel consumption of consumer goods, packaging materials, and pharmaceutical products, all of which utilize acetyl derivatives. Continuous innovation in production processes, including advancements in catalysis and feedstocks, further enhances the economic viability and environmental profile of acetyl chemicals, propelling market expansion.

Acetyl Market Executive Summary

The Acetyl Market is poised for substantial growth over the forecast period, driven by robust demand from key end-use industries and strategic technological advancements. Business trends indicate a shift towards more sustainable production methods, with companies investing in bio-based feedstocks and energy-efficient processes to meet evolving environmental regulations and consumer preferences. Furthermore, consolidation and strategic partnerships among major players are shaping the competitive landscape, aiming to optimize supply chains and expand global reach, particularly into rapidly industrializing regions.

Regional trends highlight the Asia Pacific as the dominant and fastest-growing market for acetyl products, primarily due to rapid industrialization, increasing urbanization, and expanding manufacturing bases in countries like China and India. North America and Europe, while mature markets, are experiencing growth driven by innovation in specialty chemicals and a focus on high-performance applications, alongside stringent regulatory frameworks encouraging the adoption of cleaner production technologies. Latin America and the Middle East & Africa are emerging as significant markets, spurred by infrastructure development and diversification of industrial capacities.

Segment-wise, acetic acid continues to hold the largest share owing to its fundamental role as a chemical intermediate, with strong demand from industries producing VAM, acetic anhydride, and purified terephthalic acid (PTA). The VAM segment is also experiencing notable growth, propelled by its extensive use in adhesives, paints, and films. Emerging segments, particularly those tied to specialty applications in pharmaceuticals and advanced materials, are expected to exhibit higher growth rates, reflecting ongoing research and development efforts to create value-added acetyl derivatives.

AI Impact Analysis on Acetyl Market

The integration of Artificial Intelligence (AI) across the Acetyl Market is generating considerable interest among stakeholders, with common user questions often revolving around its potential to optimize production efficiency, enhance supply chain resilience, and accelerate innovation. Users are keen to understand how AI can address the complexities of raw material price volatility, stringent environmental regulations, and the need for higher product quality and consistency. There is a strong expectation that AI-driven predictive analytics will play a pivotal role in demand forecasting, process control, and risk management, ultimately leading to more sustainable and cost-effective operations within the acetyl chemical industry.

- AI-driven predictive maintenance for manufacturing equipment, minimizing downtime and optimizing asset utilization.

- Enhanced supply chain optimization through AI algorithms that forecast demand, manage inventory, and mitigate logistical disruptions.

- Process optimization and control in chemical synthesis, leading to improved yield, reduced energy consumption, and higher product purity.

- Accelerated research and development for new acetyl derivatives and applications by simulating molecular interactions and predicting material properties.

- Advanced quality control systems utilizing machine vision and AI for real-time defect detection and adherence to stringent specifications.

- Improved safety protocols and risk management through AI-powered monitoring and anomaly detection in plant operations.

- Sustainable manufacturing practices through AI optimization of energy consumption and waste reduction processes.

- Market intelligence and competitive analysis, leveraging AI to process vast datasets for strategic decision-making.

DRO & Impact Forces Of Acetyl Market

The Acetyl Market is subject to a dynamic interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces shaping its trajectory. Key drivers include the robust and expanding demand from downstream industries such as automotive, construction, packaging, and textiles, particularly in burgeoning economies. The versatility of acetyl derivatives in producing a wide array of intermediate chemicals and end products ensures a continuous demand baseline. Furthermore, advancements in production technologies aimed at improving efficiency and reducing environmental footprint, coupled with government initiatives promoting sustainable manufacturing, also act as significant market drivers.

However, the market faces several notable restraints. Price volatility of essential raw materials, primarily crude oil and natural gas derivatives, directly impacts production costs and profit margins for acetyl manufacturers. Stringent environmental regulations pertaining to chemical emissions, waste disposal, and the use of certain chemicals pose compliance challenges and necessitate substantial investments in cleaner technologies. Additionally, the availability of alternative products or processes in certain applications, alongside intense competition among key players, can exert downward pressure on pricing and market share.

Despite these restraints, numerous opportunities are emerging that could fuel future growth. The increasing focus on bio-based acetyls derived from renewable feedstocks presents a substantial avenue for sustainable product development and market differentiation. Expansion into untapped markets in developing regions, coupled with the growth of niche applications in specialty chemicals, pharmaceuticals, and advanced materials, offers significant growth potential. Continuous innovation in catalysis and process intensification technologies will further enhance economic viability and support market expansion by improving resource efficiency and reducing operational costs. These collective impact forces necessitate strategic planning and adaptive business models for sustained success in the acetyl market.

Segmentation Analysis

The Acetyl Market is broadly segmented based on product type, application, and end-use industry, providing a granular view of its diverse dynamics. This segmentation allows for a detailed understanding of consumer preferences, technological advancements, and regional demand patterns within the intricate value chain of acetyl chemicals. Each segment plays a crucial role in the overall market landscape, driven by specific industrial requirements and economic factors.

- By Product Type:

- Acetic Acid

- Acetic Anhydride

- Vinyl Acetate Monomer (VAM)

- Ethyl Acetate

- Butyl Acetate

- Cellulose Acetate

- Others (e.g., Acetyl Chloride, Acetaldehyde)

- By Application:

- Adhesives & Sealants

- Paints & Coatings

- Textiles

- Pharmaceuticals

- Food & Beverages

- Packaging

- Chemical Intermediates

- Others (e.g., Agrochemicals, Personal Care)

- By End-Use Industry:

- Automotive

- Construction

- Consumer Goods

- Electronics

- Agriculture

- Healthcare

- Others

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Acetyl Market

The value chain for the Acetyl Market is complex and encompasses several stages, from raw material sourcing to end-product distribution, involving a multitude of stakeholders. Upstream analysis focuses on the procurement of primary feedstocks, predominantly methanol and carbon monoxide for acetic acid production, and ethylene for vinyl acetate monomer. The availability, pricing, and stability of these petrochemical raw materials significantly influence the cost structure and profitability of acetyl chemical manufacturers. Key suppliers often include major oil and gas companies, as well as specialized chemical producers. Understanding the dynamics of these upstream markets is critical for mitigating supply chain risks and ensuring operational continuity.

Downstream analysis involves the transformation of acetyl intermediates into finished products for various applications. This stage includes the production of polymers, solvents, and other derivatives that are then used by industries such as automotive, construction, textiles, and pharmaceuticals. For example, acetic acid is converted into VAM for adhesives and coatings, or into cellulose acetate for textile fibers. The efficiency of these conversion processes, along with the performance requirements of the end-use applications, dictates the demand for specific acetyl products. Innovation at this stage, particularly in developing high-performance or sustainable derivatives, can create significant market value.

Distribution channels for acetyl products are multi-faceted, involving both direct and indirect routes to market. Direct distribution typically involves sales from large manufacturers to major industrial end-users through long-term contracts, often facilitated by a dedicated sales force and logistics network. Indirect channels rely on a network of distributors, agents, and traders who procure bulk quantities and then supply smaller industrial clients or regional markets. This often includes specialized chemical distributors who can provide technical support and manage inventory for a diverse client base. The choice of distribution channel is influenced by factors such as product volume, geographic reach, customer size, and the need for specialized handling or regulatory compliance, ensuring efficient delivery to a broad spectrum of customers worldwide.

Acetyl Market Potential Customers

The potential customers for the Acetyl Market are highly diverse, spanning numerous industries that rely on acetyl derivatives as critical raw materials, intermediates, or functional additives. These end-users and buyers range from large multinational corporations to specialized small and medium-sized enterprises across various sectors. The automotive industry represents a significant customer base, utilizing acetyl-based polymers and coatings for vehicle components, interior textiles, and exterior finishes, driven by demand for lightweight materials and durable surfaces.

The construction sector is another major end-user, with a strong demand for adhesives, sealants, paints, and coatings that incorporate vinyl acetate monomer and other acetyl derivatives for their binding, protective, and decorative properties. Manufacturers of consumer goods, including packaging materials, electronics, and household products, also constitute a substantial customer segment. Acetyl products are integral to the production of plastics, films, and various chemical formulations that enhance product performance and shelf life.

Furthermore, the pharmaceutical and food & beverage industries are key consumers of acetyl derivatives. In pharmaceuticals, acetic anhydride is used in the synthesis of active pharmaceutical ingredients (APIs) and excipients, while ethyl acetate serves as a solvent. The food industry utilizes certain acetyl derivatives as flavorings, preservatives, or pH regulators. Textile manufacturers, pulp and paper producers, and agricultural chemical companies also represent vital customer segments, leveraging the unique properties of acetyl chemicals for their specific product lines and processing needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 17.2 Billion |

| Market Forecast in 2033 | USD 27.3 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Celanese Corporation, BASF SE, Eastman Chemical Company, LyondellBasell Industries N.V., Wacker Chemie AG, Sinopec Corp., Mitsubishi Chemical Corporation, BP p.l.c., Daicel Corporation, Saudi International Petrochemical Company (SIPCHEM), Formosa Plastics Corporation, Reliance Industries Limited, Showa Denko K.K., LG Chem Ltd., Arkema S.A., Shandong Hualu-Hengsheng Chemical Co. Ltd., Kingboard Chemical Holdings Limited, Yankuang Group Co. Ltd., China National Petroleum Corporation (CNPC), Sasol Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acetyl Market Key Technology Landscape

The Acetyl Market's technological landscape is continuously evolving, driven by the imperative to enhance efficiency, reduce costs, and improve environmental performance. Key technologies employed in the production of core acetyl chemicals, such as acetic acid and vinyl acetate monomer (VAM), are critical differentiators for manufacturers. The predominant method for acetic acid synthesis is the carbonylation of methanol, with catalyst systems like Monsanto and Cativa processes being industry standards. Ongoing research focuses on improving catalyst activity, selectivity, and stability, as well as exploring non-iodine-based catalytic systems to reduce corrosion and simplify separation processes, thereby lowering operational expenditures and environmental impact.

For vinyl acetate monomer (VAM) production, the vapor-phase catalytic reaction of ethylene, acetic acid, and oxygen remains the primary technology. Advancements in this area involve the development of novel palladium-gold alloy catalysts and improved reactor designs that enhance conversion rates and reduce by-product formation. Furthermore, the integration of process intensification techniques, such as reactive distillation and microreactors, is gaining traction. These technologies aim to combine multiple unit operations into a single step, leading to smaller plant footprints, lower capital costs, and significantly improved energy efficiency. The adoption of advanced process control systems and real-time analytics further optimizes these complex chemical reactions, ensuring consistent product quality and operational stability.

Beyond core production, the market is also seeing significant technological shifts in sustainable and bio-based acetyl production. Research into converting biomass and waste streams into acetic acid and its derivatives through fermentation or gasification routes is advancing rapidly, driven by environmental concerns and the desire to reduce reliance on fossil feedstocks. Innovations in purification and separation technologies, including membrane separation and advanced distillation techniques, are also crucial for achieving high purity products and minimizing energy consumption. The broader application of digital technologies, including AI and IoT for predictive maintenance and smart manufacturing, is transforming plant operations, leading to unprecedented levels of efficiency, safety, and responsiveness in the acetyl chemical industry.

Regional Highlights

- Asia Pacific: Dominates the global acetyl market, driven by rapid industrialization, burgeoning manufacturing sectors in China and India, and increasing demand from construction, automotive, and packaging industries. The region benefits from lower production costs and a large consumer base.

- North America: A mature market characterized by significant investments in specialty chemicals, advanced manufacturing, and sustainable production practices. Growth is supported by demand from pharmaceuticals, food and beverages, and high-performance materials sectors, coupled with a strong emphasis on regulatory compliance.

- Europe: Exhibits steady growth, focusing on innovation in sustainable and bio-based acetyls, as well as high-value applications in automotive and aerospace. Stringent environmental regulations drive the adoption of cleaner technologies and efficient production processes.

- Latin America: An emerging market with growth potential spurred by increasing industrial activity, infrastructure development, and expanding consumer markets. Countries like Brazil and Mexico are key contributors, driven by demand from paints and coatings, adhesives, and packaging.

- Middle East & Africa (MEA): Showing nascent growth, primarily driven by petrochemical expansion initiatives and diversification efforts away from crude oil exports. Investments in chemical manufacturing capacities and growing domestic demand are fostering market development, particularly in Saudi Arabia and UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acetyl Market.- Celanese Corporation

- BASF SE

- Eastman Chemical Company

- LyondellBasell Industries N.V.

- Wacker Chemie AG

- Sinopec Corp.

- Mitsubishi Chemical Corporation

- BP p.l.c.

- Daicel Corporation

- Saudi International Petrochemical Company (SIPCHEM)

- Formosa Plastics Corporation

- Reliance Industries Limited

- Showa Denko K.K.

- LG Chem Ltd.

- Arkema S.A.

- Shandong Hualu-Hengsheng Chemical Co. Ltd.

- Kingboard Chemical Holdings Limited

- Yankuang Group Co. Ltd.

- China National Petroleum Corporation (CNPC)

- Sasol Ltd.

Frequently Asked Questions

What are the primary drivers for the growth of the Acetyl Market?

The primary drivers include increasing demand from key end-use industries like automotive, construction, and packaging, particularly in emerging economies. Additionally, technological advancements in production processes and a growing focus on sustainable chemicals contribute significantly to market expansion.

Which product type holds the largest share in the Acetyl Market?

Acetic acid typically holds the largest market share due to its fundamental role as a versatile chemical intermediate. It is a key building block for a wide range of derivatives such as VAM, acetic anhydride, and various esters, driving its extensive demand across numerous industries.

What impact do raw material price fluctuations have on the Acetyl Market?

Raw material price fluctuations, especially for feedstocks like methanol, carbon monoxide, and ethylene derived from crude oil and natural gas, significantly impact the Acetyl Market. Such volatility directly affects production costs, profit margins, and the overall competitiveness of acetyl chemical manufacturers.

How is the Asia Pacific region contributing to the Acetyl Market's growth?

The Asia Pacific region is a dominant and rapidly growing market for acetyls, driven by its robust industrialization, expanding manufacturing bases, and significant infrastructure development in countries like China and India. The region's large consumer base and increasing demand from downstream sectors are key growth accelerators.

What are the key opportunities for innovation in the Acetyl Market?

Key opportunities for innovation include the development of bio-based acetyls from renewable feedstocks, which aligns with sustainability goals and reduces reliance on fossil resources. Further opportunities lie in process intensification technologies, advanced catalyst systems, and the integration of AI for optimized production and supply chain management.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Chloroacetyl Chloride Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Acetyl Chloride Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Acetyl Tributyl Citrate (ATBC) Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Acetyl Triethyl Citrate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Acetyl Isovaleryl Market Statistics 2025 Analysis By Application (Food Industry, Beverage Industry, Chemical Industry, Others), By Type (Liquid Form, Powder Form), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager