Angle Grinder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440173 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Angle Grinder Market Size

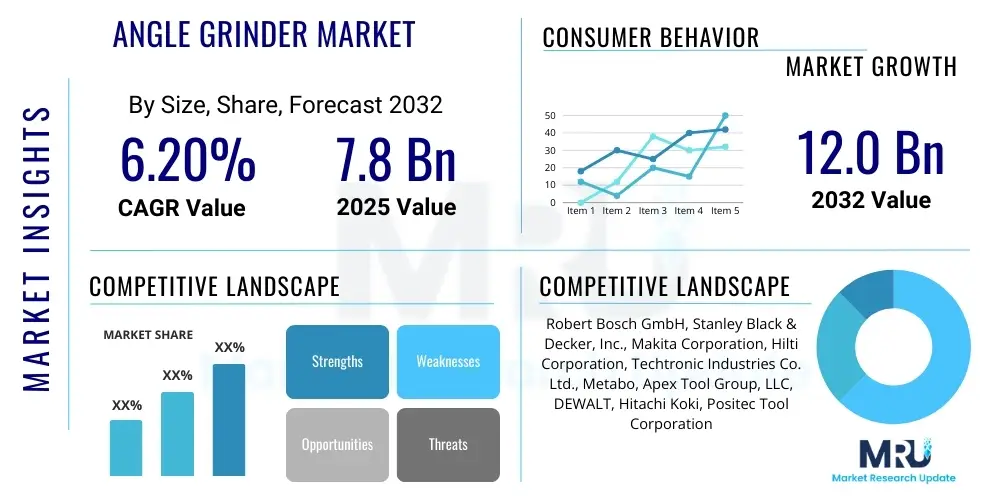

The Angle Grinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033.

Angle Grinder Market introduction

The angle grinder market encompasses the global production, distribution, and sale of handheld power tools designed for various tasks such as cutting, grinding, polishing, and sanding. These versatile tools are characterized by a rotating abrasive disc or wheel mounted at a right angle to the drive shaft, hence their name. Historically, angle grinders have been indispensable in heavy industries, construction, and metal fabrication due to their robust performance and adaptability. Their evolution has seen advancements from basic corded models to sophisticated cordless units, incorporating features like brushless motors, enhanced battery technology, and improved safety mechanisms, catering to both professional and DIY users.

Major applications for angle grinders span across a diverse range of sectors, including construction for cutting rebar, concrete, and masonry; metalworking for grinding welds, deburring edges, and polishing surfaces; automotive repair for rust removal and component fabrication; and general fabrication for shaping and finishing various materials. The widespread utility of angle grinders stems from their ability to handle tough materials with precision and efficiency, significantly reducing manual labor and improving productivity. Their benefits include high power output, versatility in accessory attachments, portability, and the capacity to work in confined spaces, making them a cornerstone tool in numerous trades and workshops worldwide.

Several driving factors propel the growth of the angle grinder market. Continuous infrastructure development globally, particularly in emerging economies, fuels demand for robust construction tools. The resurgence and expansion of manufacturing sectors, especially in automotive, aerospace, and general fabrication, necessitate efficient metalworking equipment. Furthermore, the increasing trend of do-it-yourself (DIY) projects and home renovation activities among consumers contributes significantly to market expansion, driving demand for more accessible and user-friendly angle grinder models. Technological advancements, such as improved battery life for cordless models and enhanced safety features, also play a crucial role in attracting new users and encouraging upgrades among existing ones, reinforcing the market's upward trajectory.

Angle Grinder Market Executive Summary

The angle grinder market is experiencing dynamic shifts driven by evolving business trends, distinct regional growth patterns, and technological advancements within specific segments. Business trends highlight a strong emphasis on cordless technology, with manufacturers investing heavily in developing more powerful and longer-lasting battery systems to enhance user mobility and convenience. E-commerce platforms are becoming increasingly vital distribution channels, offering wider reach and competitive pricing, while strategic partnerships between tool manufacturers and construction/industrial firms are consolidating market presence. Furthermore, there is a growing demand for smart tools equipped with IoT capabilities for predictive maintenance and performance monitoring, signaling a move towards more integrated and data-driven solutions in professional environments.

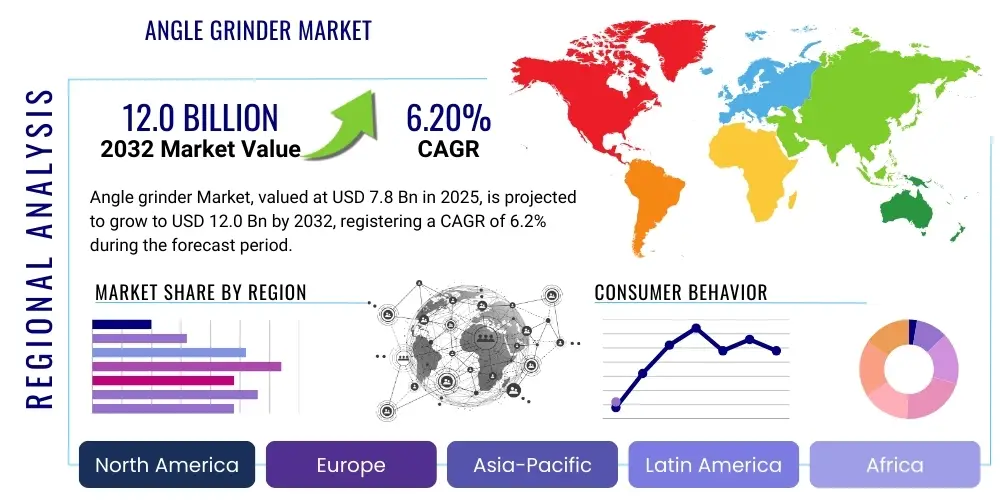

Regionally, the Asia Pacific (APAC) market stands out as a primary growth engine, fueled by rapid urbanization, extensive infrastructure projects, and a burgeoning manufacturing base, particularly in countries like China and India. North America and Europe, while mature markets, continue to demonstrate stable demand, driven by stringent safety regulations that encourage the adoption of newer, compliant models, as well as a strong DIY culture and innovation in professional-grade tools. Latin America and the Middle East & Africa (MEA) are emerging as promising markets, albeit with slower growth rates, as industrialization efforts and increased construction activities gradually contribute to market expansion. Each region presents unique consumer preferences and regulatory landscapes that influence product development and market penetration strategies.

Segmentation trends reveal a significant shift towards cordless angle grinders, which are steadily gaining market share over traditional corded models due to their portability and flexibility, especially in remote or power-limited job sites. While larger disc diameter angle grinders remain essential for heavy-duty industrial applications, there is also a robust demand for compact, lightweight models for precision work and DIY tasks. The end-user segment shows strong growth in both professional and consumer categories, necessitating a diverse product portfolio from manufacturers. In terms of power source, electric angle grinders dominate, but pneumatic variants hold niche importance in certain industrial settings where safety or specific power requirements dictate their use. These trends underscore a market that is increasingly diversified, catering to a broad spectrum of user needs and operational contexts.

AI Impact Analysis on Angle Grinder Market

User inquiries regarding the impact of Artificial Intelligence on the angle grinder market predominantly revolve around questions of enhanced functionality, predictive maintenance, operator safety, and potential automation. Common themes include how AI could lead to smarter, more adaptive tools, whether it can prevent common accidents, and if it might enable more efficient operation or even robotic integration. Users are interested in features like AI-powered feedback mechanisms that optimize grinding pressure or speed, diagnostic capabilities that anticipate tool wear, and intelligent safety systems that react proactively to hazardous situations. There's also curiosity about AI's role in design optimization for better ergonomics and material compatibility, aiming for a future where angle grinders are not just powerful, but also intuitively smart and safer to operate.

- AI-driven predictive maintenance systems can monitor tool usage patterns and component wear, alerting users to potential failures before they occur, thus extending tool lifespan and minimizing downtime.

- Integration of AI could lead to adaptive power delivery, where the tool automatically adjusts torque and RPM based on the material and task, optimizing performance and reducing user fatigue.

- Enhanced safety features leveraging AI could include intelligent kickback detection and prevention systems that react faster than current mechanical solutions, or even proximity sensors that disable the tool when an operator's hand is too close to the disc.

- AI can optimize manufacturing processes for angle grinder components, leading to more durable materials, improved motor efficiency, and superior ergonomic designs through generative design algorithms.

- For advanced industrial applications, AI could facilitate the integration of angle grinders into robotic systems, enabling automated grinding, cutting, and deburring tasks with greater precision and consistency, particularly in repetitive or hazardous environments.

- Real-time operational feedback systems powered by AI could provide operators with actionable insights, guiding them to achieve optimal results and reduce material wastage.

- AI can be utilized in quality control during the manufacturing of angle grinder abrasive discs and accessories, ensuring higher consistency and performance standards across product batches.

DRO & Impact Forces Of Angle Grinder Market

The Angle Grinder Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, shaped by broader economic and technological impact forces. Key drivers include robust global infrastructure development projects, which necessitate heavy-duty cutting and grinding tools, particularly in emerging economies. The sustained growth of the manufacturing sector, especially automotive, construction, and metal fabrication, consistently fuels demand for efficient and versatile angle grinders. Moreover, the increasing popularity of DIY and home improvement projects among consumers, driven by accessibility to tools and online tutorials, further contributes to market expansion. Technological advancements, such as the development of more powerful and longer-lasting cordless batteries, brushless motors, and enhanced safety features, also act as significant drivers, encouraging adoption and upgrades.

Conversely, several restraints impede market growth. Primary among these are the inherent safety concerns associated with angle grinder use, including risks of injury from kickback, flying debris, and accidental cuts, which can deter potential users and lead to stringent regulatory oversight. The high noise and vibration levels produced by these tools not only contribute to user fatigue but also pose long-term health risks, demanding ergonomic and noise reduction innovations. Intense market competition, characterized by a proliferation of brands offering a wide range of products at varying price points, puts pressure on profit margins and necessitates continuous product differentiation. Additionally, a shortage of skilled labor capable of safely and efficiently operating specialized power tools in some regions can limit adoption in complex industrial applications.

Despite these challenges, substantial opportunities exist for market players. The burgeoning growth in emerging markets, particularly across Asia Pacific and parts of Latin America, presents untapped potential for expansion, driven by industrialization and urbanization. Continuous innovation in cordless technology, focusing on improved power-to-weight ratios, faster charging times, and greater battery interchangeability across tool lines, will open new application possibilities and attract professional users seeking maximum portability. The integration of smart features, such as IoT connectivity for tool tracking, predictive maintenance, and operational analytics, offers a competitive edge by enhancing efficiency and reducing operational costs. Furthermore, a focus on developing more ergonomic designs, advanced anti-vibration systems, and superior dust management solutions can mitigate existing restraints and cater to evolving user demands for comfort and safety. The impact forces from Porter's Five Forces analysis highlight significant competitive rivalry due to many established players, moderate bargaining power of buyers given product variety, and a relatively low threat of substitutes due to the unique functionality of angle grinders, while the threat of new entrants is moderate due to capital investment and brand loyalty requirements.

Segmentation Analysis

The angle grinder market is comprehensively segmented to reflect the diverse applications, technological specifications, and end-user requirements that characterize its global landscape. This segmentation allows for a detailed understanding of market dynamics, growth drivers, and competitive strategies across various product categories and consumer groups. The primary methods of segmentation typically revolve around the tool's power source, disc diameter, application, and the end-user profile, each providing unique insights into consumer preferences and market demand patterns. Understanding these segments is crucial for manufacturers to tailor their product offerings, marketing efforts, and distribution channels effectively, addressing the specific needs of different market niches from heavy industrial users to casual DIY enthusiasts.

- By Type:

- Corded Angle Grinders

- Cordless Angle Grinders

- By Power Source:

- Electric

- Pneumatic

- Hydraulic

- By Disc Diameter:

- 4-5 inches (100-125mm)

- 6-7 inches (150-180mm)

- 9+ inches (230mm and above)

- By Application:

- Metalworking

- Construction

- Automotive

- General Fabrication

- DIY/Home Improvement

- Woodworking

- By End-User:

- Industrial

- Commercial

- Residential

- By Sales Channel:

- Online

- Offline (Retail Stores, Distributors, Wholesalers)

Value Chain Analysis For Angle Grinder Market

The value chain for the Angle Grinder Market begins with an intricate upstream analysis, focusing on the sourcing of critical raw materials and components. This stage involves the procurement of high-grade steel for gears and housing, robust plastics for casings, copper for motor windings, and various electronic components for speed control and safety features. Key suppliers in this segment include specialized manufacturers of electric motors, battery cells (for cordless models), precision bearings, and abrasive disc materials. The quality and cost-effectiveness of these upstream inputs directly influence the final product's performance, durability, and market competitiveness. Relationships with reliable component suppliers are crucial for maintaining consistent production quality and managing supply chain risks, especially with global sourcing strategies.

Moving downstream, the value chain encompasses the manufacturing, assembly, and rigorous quality control processes where components are transformed into finished angle grinders. This stage involves significant investment in automation, skilled labor, and advanced production techniques to ensure product consistency, safety compliance, and efficiency. Once manufactured, the products enter the distribution channels, which are bifurcated into direct and indirect routes. Direct distribution involves manufacturers selling directly to large industrial clients, professional contractors, or through their own online stores, allowing for greater control over pricing and customer relationships. This approach often caters to specialized or high-volume orders, providing a direct feedback loop for product improvement.

Indirect distribution forms the backbone of market reach, leveraging a vast network of wholesalers, distributors, hardware stores, and general retailers. These intermediaries play a crucial role in stocking, marketing, and selling angle grinders to a broad customer base, including small businesses, tradespeople, and individual DIY enthusiasts. The effectiveness of indirect channels hinges on strong partnerships, efficient logistics, and comprehensive retail presence. The rise of e-commerce platforms has also significantly transformed indirect distribution, enabling manufacturers and retailers to reach a global audience with unprecedented ease, offering competitive pricing, and vast product selections. This multi-channel approach ensures maximum market penetration and caters to diverse buying preferences, solidifying the market's extensive reach from industrial procurement to individual consumer purchases.

Angle Grinder Market Potential Customers

The angle grinder market caters to a broad and diverse spectrum of potential customers, segmented primarily by their end-use applications and operational scale. One of the largest customer groups comprises professionals in the construction industry. This includes general contractors, masons, plumbers, electricians, and welders who rely on angle grinders for tasks such as cutting rebar, concrete, pipes, and tiles, as well as grinding welds and preparing surfaces for finishing. Their demand is typically for robust, high-power, and durable tools capable of enduring demanding job site conditions, often favoring larger disc diameters and advanced safety features to maximize productivity and minimize downtime in challenging environments.

Another significant customer segment is found within the metalworking and fabrication industries. This encompasses automotive repair shops, metal fabricators, shipbuilding yards, and general workshops where angle grinders are indispensable for grinding welds, deburring sharp edges, cutting metal sheets and profiles, and preparing surfaces for painting or assembly. These users often require tools with precise control, variable speed settings, and compatibility with a range of abrasive and cutting discs to achieve specific finishes and meet exacting industry standards. Reliability and performance under continuous heavy use are paramount for these professional end-users, driving demand for premium, industrial-grade models.

Beyond industrial and professional use, the rapidly expanding segment of DIY enthusiasts and residential users represents a substantial and growing customer base. These individuals utilize angle grinders for various home improvement projects, garden maintenance, minor repairs, and hobby-related tasks such as metal sculpting or restoration. Their preferences lean towards more compact, lightweight, and user-friendly models, often cordless, that offer sufficient power for occasional use without being overly complex or expensive. Retailers and manufacturers targeting this segment often emphasize affordability, ease of use, safety features suitable for novice users, and versatile attachments to attract a broader consumer audience. This diversified customer landscape necessitates a comprehensive product portfolio from manufacturers to capture market share effectively across all tiers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch, Makita, DeWalt, Milwaukee Tool, Hilti, Metabo, Ryobi, Black+Decker, HiKOKI Power Tools (formerly Hitachi), Stanley FatMax, Worx, Porter-Cable, Skil, Festool, Fein, Einhell, Dremel, Ridgid, Craftsman, Snap-on |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Angle Grinder Market Key Technology Landscape

The Angle Grinder Market's technological landscape is characterized by continuous innovation aimed at enhancing performance, safety, and user convenience. A pivotal advancement is the widespread adoption of brushless motor technology, which offers significant advantages over traditional brushed motors. Brushless motors provide higher efficiency, resulting in longer battery life for cordless models and reduced heat generation, thereby extending tool lifespan and minimizing maintenance. They also deliver more consistent power output and higher torque, crucial for demanding applications. This technology, combined with advanced electronic control systems, allows for features like constant speed under load, variable speed settings for different materials, and electronic overload protection, significantly improving operational precision and versatility.

Battery technology, particularly lithium-ion (Li-ion) advancements, has revolutionized the cordless angle grinder segment. Modern Li-ion battery packs offer higher energy density, providing longer runtimes and faster charging capabilities compared to older battery chemistries. Innovations in battery management systems (BMS) further optimize performance by preventing overcharging, deep discharge, and overheating, thus enhancing battery longevity and safety. Furthermore, the development of integrated tool-and-battery ecosystems, where batteries are interchangeable across a range of tools from the same manufacturer, offers significant convenience and cost savings for users, driving the shift from corded to cordless solutions, especially for professional users who prioritize mobility and efficiency on job sites.

Beyond core power and battery innovations, the market is also witnessing a surge in smart features and safety enhancements. Anti-kickback technology, which rapidly shuts down the tool when a bind-up is detected, has become a standard safety feature, significantly reducing the risk of severe injury. Vibration reduction systems, often incorporating advanced damping mechanisms in handles and motor mounts, aim to minimize user fatigue and mitigate long-term health issues associated with prolonged tool use. Dust management solutions, including dust extraction ports and shrouds that connect to vacuum systems, are crucial for maintaining cleaner work environments and complying with health and safety regulations. Emerging technologies include the integration of IoT connectivity for tool tracking, remote diagnostics, and performance monitoring, offering a glimpse into a future of connected and data-driven power tools that optimize productivity and operational efficiency in industrial and commercial settings.

Regional Highlights

- North America: This region represents a mature yet stable market for angle grinders, characterized by high adoption rates in construction, manufacturing, and a robust DIY culture. Demand is driven by infrastructure upgrades, residential remodeling, and stringent safety standards that encourage replacement of older tools with newer, compliant models featuring advanced safety features. Key players maintain strong market presence through extensive distribution networks and brand loyalty.

- Europe: Similar to North America, Europe is a well-established market with a strong emphasis on professional-grade tools and adherence to strict health and safety regulations. Innovation in ergonomic design, vibration reduction, and cordless technology is particularly prominent here. Countries like Germany and the UK show consistent demand due to strong industrial bases and construction activities, while Eastern European markets present growth opportunities.

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by rapid industrialization, extensive urbanization, and massive infrastructure development projects, especially in China, India, and Southeast Asian nations. The region sees demand for both high-end professional tools and more affordable options for a large and expanding labor force. Increased disposable incomes also contribute to the rise in DIY activities.

- Latin America: This region is an emerging market with gradual growth driven by expanding construction sectors and industrial activities in countries like Brazil and Mexico. Economic volatility can impact market stability, but long-term prospects are positive due to ongoing development. Demand is often price-sensitive, balancing performance with affordability.

- Middle East and Africa (MEA): The MEA region is experiencing steady growth, primarily fueled by large-scale construction projects, oil and gas infrastructure, and diversification efforts in several economies. While growth rates may be slower than APAC, ongoing development in countries like Saudi Arabia, UAE, and South Africa ensures a consistent demand for power tools, including angle grinders, with a focus on robust and durable equipment for demanding climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Angle Grinder Market.- Robert Bosch GmbH (Bosch Power Tools)

- Makita Corporation

- Stanley Black & Decker (DeWalt, Black+Decker, Porter-Cable, Craftsman)

- Milwaukee Tool (Techtronic Industries Co. Ltd.)

- Hilti Corporation

- Metabo (Koki Holdings Co., Ltd.)

- Ryobi (Techtronic Industries Co. Ltd.)

- HiKOKI Power Tools (Koki Holdings Co., Ltd.)

- Festool (TTS Tooltechnic Systems AG & Co. KG)

- Fein Power Tools AG

- Einhell Germany AG

- Dremel (Robert Bosch Tool Corporation)

- Skil (Chervon North America Inc.)

- Ridgid (Emerson Electric Co.)

- Snap-on Incorporated

- Kawasaki Heavy Industries, Ltd.

- JCB (JC Bamford Excavators Ltd.)

- Hitachi Koki (rebranded as HiKOKI)

- Ingersoll Rand Inc.

- Apex Tool Group (Allen, Armstrong, Crescent)

Frequently Asked Questions

Analyze common user questions about the Angle Grinder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an angle grinder primarily used for?

Angle grinders are versatile power tools primarily used for cutting, grinding, and polishing various materials such as metal, stone, concrete, and tile. They are essential in construction, metalworking, automotive repair, and DIY projects for tasks like cutting rebar, smoothing welds, removing rust, and shaping materials.

What are the key differences between corded and cordless angle grinders?

Corded angle grinders offer continuous power supply, typically higher sustained torque, and are generally more powerful for heavy-duty tasks, but they require a power outlet. Cordless angle grinders provide superior portability and flexibility, powered by rechargeable batteries, making them ideal for remote job sites or areas without easy power access, though they may have limited runtime depending on battery capacity.

What safety precautions should be taken when operating an angle grinder?

Crucial safety precautions include wearing appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, gloves, and a dust mask. Always ensure the workpiece is securely clamped, use the correct disc for the material, maintain a firm grip, keep guards in place, and be aware of kickback risks. Never remove the guard or operate without proper training.

How do I choose the right size angle grinder for my needs?

The right size angle grinder depends on the task and material. Smaller 4-5 inch (100-125mm) grinders are suitable for lighter tasks, precision work, and DIY. Medium 6-7 inch (150-180mm) grinders offer a balance of power and maneuverability for general fabrication and heavier DIY. Larger 9+ inch (230mm+) grinders are reserved for heavy-duty industrial cutting and grinding of thick materials, providing maximum power but less agility.

What technological advancements are impacting the angle grinder market?

Key technological advancements include brushless motors for increased efficiency and lifespan, advanced lithium-ion battery technology for longer runtimes in cordless models, enhanced safety features like anti-kickback protection and vibration reduction, and smart features such as IoT connectivity for tool tracking and predictive maintenance. These innovations aim to improve performance, user safety, and overall productivity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Power Angle Grinder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Variable Speed Angle Grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Angle grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Angle Grinder Market Statistics 2025 Analysis By Application (Metal Processing, Wood Processing, Construction), By Type (Electric Angle Grinder, Pneumatic Angle Grinder), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager