Angle grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427747 | Date : Oct, 2025 | Pages : 244 | Region : Global | Publisher : MRU

Angle grinder Market Size

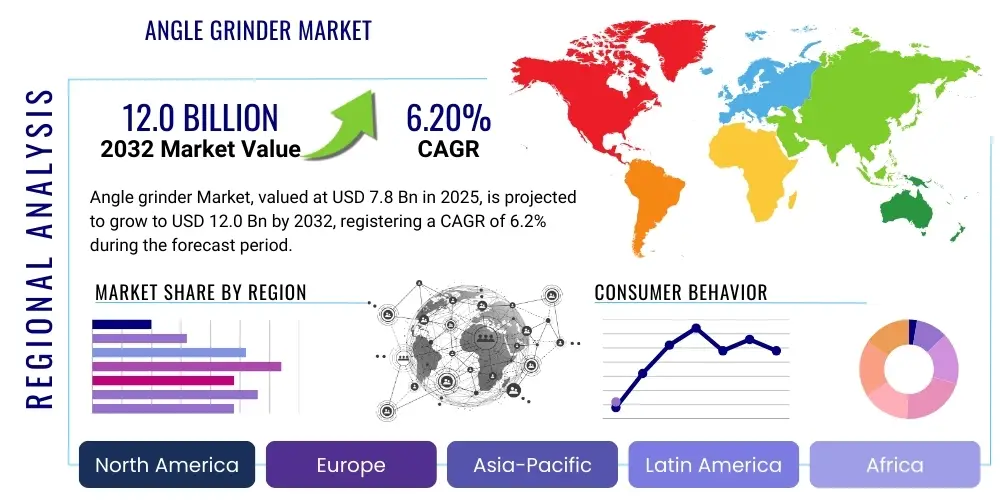

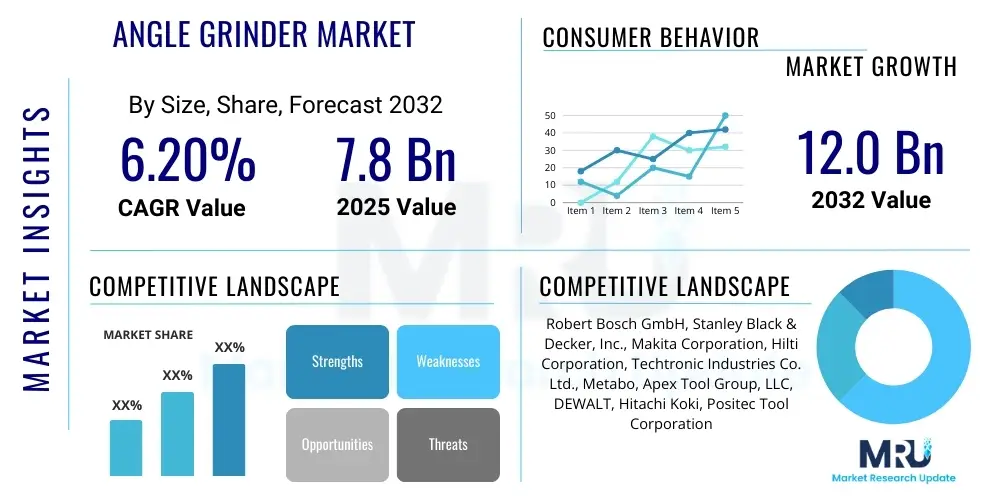

The Angle grinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 7.8 billion in 2025 and is projected to reach USD 12.0 billion by the end of the forecast period in 2032. This robust growth trajectory is underpinned by sustained demand across diverse end-use industries, including construction, automotive, and metal fabrication, where angle grinders are indispensable for cutting, grinding, and polishing tasks. The increasing focus on infrastructure development in emerging economies, coupled with a steady demand for DIY and home improvement projects, further propels market expansion. Technological advancements, particularly in battery life, motor efficiency, and ergonomic design, contribute significantly to product adoption and market valuation. Moreover, the replacement cycle for existing tools, driven by enhanced features and performance, consistently contributes to market vitality, ensuring a stable revenue stream for manufacturers and distributors alike throughout the forecast period.

Angle grinder Market introduction

The angle grinder market encompasses a wide array of handheld power tools utilized for cutting, grinding, and polishing various materials such as metal, stone, concrete, and tile. These versatile devices are characterized by a rotating abrasive disc or cutting wheel attached at a right angle to the drive motor, offering high rotational speeds and significant torque for efficient material removal and shaping. Major applications span critical industrial sectors including construction, where they are essential for site preparation and finishing work; metalworking and fabrication, for deburring, weld preparation, and material shaping; automotive repair and manufacturing, for bodywork and component modification; and even in significant DIY and home improvement projects requiring precise material adjustments. The primary benefits of angle grinders include their unparalleled versatility, enabling a single tool to perform multiple functions; their portability, facilitating ease of use in diverse work environments; and their efficiency, significantly reducing manual labor and project timelines. The market’s consistent expansion is primarily driven by global infrastructure development initiatives, rapid industrialization in developing regions, the burgeoning trend of do-it-yourself (DIY) activities among consumers, and continuous innovation in product design and functionality. Furthermore, the inherent need for robust and reliable tools in demanding professional settings ensures a perpetual demand cycle, fostering ongoing investment in research and development by leading manufacturers to enhance performance, safety, and user experience, thereby sustaining the market’s growth momentum.

Angle grinder Market Executive Summary

The Angle grinder Market is currently experiencing dynamic shifts driven by several key business, regional, and segmental trends. From a business perspective, there is a pronounced move towards cordless solutions, fueled by advancements in lithium-ion battery technology, which offer greater portability and operational flexibility, thus enhancing productivity on job sites. Manufacturers are also heavily investing in ergonomic designs, anti-vibration technologies, and advanced safety features like kickback protection and rapid braking systems to reduce user fatigue and enhance operational security, thereby driving consumer preference for premium, feature-rich models. Sustainability and material efficiency are increasingly influencing product development, with a focus on durable components and energy-efficient motors. Regionally, Asia-Pacific remains the dominant and fastest-growing market, primarily due to large-scale infrastructure projects, rapid urbanization, and a booming manufacturing sector, particularly in countries like China and India. North America and Europe, while mature markets, exhibit stable demand, characterized by a preference for high-performance, professional-grade tools and a strong emphasis on workplace safety standards, which encourages the adoption of technologically advanced grinders. Latin America and the Middle East & Africa are emerging as significant growth pockets, driven by nascent industrialization and increasing construction activities. Segment-wise, the cordless angle grinder segment is projected to outpace its corded counterpart, reflecting the broader industry trend towards mobility and convenience. Brushless motor technology is gaining substantial traction across all power tiers, owing to its superior efficiency, extended tool life, and reduced maintenance requirements. Furthermore, demand for various disc diameters is dictated by specific application requirements, with larger discs favored in heavy industrial settings and smaller ones for precision work and confined spaces, illustrating a diverse but specialized market demand profile that manufacturers are actively addressing through product diversification and innovation.

AI Impact Analysis on Angle grinder Market

The integration of Artificial Intelligence (AI) is poised to significantly transform various facets of the Angle grinder Market, addressing common user questions and concerns regarding enhanced safety, predictive maintenance, and optimized performance. Users are increasingly curious about how AI can make angle grinders inherently safer, especially given the historical accident rates associated with these powerful tools. They also question AI’s potential to optimize manufacturing processes for angle grinders, improving quality control and reducing production costs. Furthermore, theres a strong expectation that AI could usher in an era of smart tools capable of self-diagnosis, performance tuning, and even guided operation. The underlying theme revolves around leveraging AI to mitigate operational risks, streamline the entire product lifecycle from design to end-use, and elevate the user experience through intelligent functionalities that enhance both efficiency and safety, thereby setting new benchmarks for tool innovation and user confidence in demanding professional environments.

- Enhanced predictive maintenance by analyzing usage patterns and motor diagnostics.

- Integration of smart safety features like AI-powered kickback detection and automatic shut-off.

- Optimization of manufacturing processes for precision engineering and reduced defects.

- Development of AI-driven training modules for safer and more efficient tool operation.

- Real-time performance monitoring and feedback for improved grinding efficiency.

- Supply chain optimization through AI-driven demand forecasting and inventory management.

DRO & Impact Forces Of Angle grinder Market

The Angle grinder Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, alongside significant Impact Forces that dictate its trajectory. Key drivers include the consistent growth in the global construction industry, fueled by urbanization and infrastructure development, particularly in emerging economies where extensive building projects necessitate robust cutting and grinding tools. Furthermore, the burgeoning manufacturing and metal fabrication sectors, coupled with the increasing trend of DIY and home renovation projects, contribute substantially to market demand. Technological advancements, such as the development of powerful brushless motors, longer-lasting lithium-ion batteries, and improved ergonomic designs that enhance user comfort and safety, also act as significant market accelerants, encouraging upgrades and new purchases. However, the market faces notable restraints, primarily centered around safety concerns; angle grinders, if improperly used, pose considerable risks of injury, necessitating strict safety protocols and continuous user training. The relatively high initial cost of professional-grade and technologically advanced cordless models can deter price-sensitive consumers and smaller businesses. Environmental regulations concerning noise pollution, dust generation, and the disposal of batteries and electronic waste also present operational and design challenges for manufacturers. Opportunities for growth are abundant, particularly in emerging markets with rapidly developing industrial bases and infrastructure. The expansion of the rental equipment market offers new avenues for revenue, allowing users access to high-end tools without significant upfront investment. Innovation in smart tools, featuring IoT connectivity for asset tracking, remote diagnostics, and performance optimization, represents a substantial future growth area. The impact forces within the market are characterized by intense competition among established global players and regional manufacturers, leading to continuous product differentiation and aggressive marketing strategies. Buyer power remains moderate, driven by diverse product offerings and the availability of substitutes, while supplier power for raw materials and advanced components is also moderate due to a competitive supply chain. The threat of new entrants is low due to high capital investment and established brand loyalty, although niche innovators can find traction. The threat of substitutes, such as plasma cutters or specialized saws for certain applications, is always present, compelling angle grinder manufacturers to continually innovate and enhance product versatility and efficiency to maintain market share.

Segmentation Analysis

The Angle grinder Market is extensively segmented to reflect the diverse needs and applications across various user bases and operational environments, allowing for a detailed understanding of market dynamics and targeted product development. These segmentations are critical for manufacturers to align their offerings with specific demands, ranging from high-powered tools for heavy industrial use to compact models for precision tasks and consumer-grade devices for DIY enthusiasts. The primary segmentation often revolves around power source, differentiating between corded models that offer continuous power for stationary applications and cordless versions that provide unparalleled mobility, leveraging advancements in battery technology. Further distinctions are made based on the disc diameter, which directly correlates with the tools capacity for material removal and the depth of cut, catering to different project scales. The motor type, specifically distinguishing between traditional brushed and more efficient brushless motors, also forms a crucial segmentation, influencing performance, durability, and maintenance requirements. Application-based segmentation provides insight into the predominant end-use sectors, such as construction, metal fabrication, automotive, and general maintenance, highlighting where demand is most concentrated. Lastly, the end-user profile, separating professional tradespeople from DIY consumers, helps to define product features, pricing strategies, and distribution channels, ensuring that products are optimally positioned for their intended markets and user expectations, thereby facilitating a comprehensive market analysis and strategic planning for sustained growth.

- By Power Source: Corded Angle Grinders, Cordless Angle Grinders

- By Disc Diameter: Small Angle Grinders (Up to 125mm), Large Angle Grinders (180mm and above)

- By Motor Type: Brushed Motor, Brushless Motor

- By Application: Construction, Metal Fabrication, Automotive, General Industrial, DIY/Home Improvement

- By End-User: Professional/Industrial, Residential/DIY

Angle grinder Market Value Chain Analysis

The value chain of the Angle grinder Market is a complex and interconnected network, beginning with the sourcing of raw materials and culminating in the delivery of the finished product to the end-user, encompassing both direct and indirect distribution channels. The upstream analysis reveals a reliance on a diverse set of suppliers providing essential raw materials and components, including high-grade steel for gears and spindles, durable plastics for housing and handles, copper for motor windings, advanced electronic components for controls and safety features, and increasingly, specialized materials for high-performance abrasive discs and lithium-ion cells for battery packs. These suppliers operate in a competitive environment, with manufacturers carefully selecting partners based on quality, cost-efficiency, and adherence to environmental standards. Midstream activities involve the design, manufacturing, assembly, and quality control processes undertaken by the angle grinder companies themselves, often involving sophisticated automated production lines and stringent testing protocols to ensure product reliability and safety. Downstream analysis focuses on the robust distribution network, which is multifaceted. This includes large-scale wholesalers who purchase in bulk and then distribute to various retailers, specialized industrial distributors who cater exclusively to professional trades and large enterprises, and a rapidly growing e-commerce segment that allows manufacturers to directly reach consumers or through online marketplaces. Direct distribution involves manufacturers supplying large construction firms or industrial clients directly, often with customized orders and dedicated service support. Indirect distribution, which constitutes a significant portion of the market, leverages retail channels such as hardware stores, home improvement centers, and specialized power tool dealers, ensuring broad market penetration. The efficiency of this value chain, from procurement to final delivery, is critical for competitive pricing, timely product availability, and overall market responsiveness, enabling manufacturers to meet diverse consumer demands and adapt to evolving market trends effectively. Innovations in logistics and supply chain management, often aided by digital technologies, are continually optimizing these processes to enhance speed and reduce costs across the entire value chain.

Angle grinder Market Potential Customers

The Angle grinder Market caters to a broad and diverse spectrum of potential customers, ranging from individual DIY enthusiasts to large-scale industrial enterprises, each with distinct needs and purchasing considerations. The primary end-users and buyers of angle grinders include professional tradespeople such as construction workers, masons, plumbers, and electricians, who rely on these tools for daily tasks like cutting rebar, grinding welds, and preparing surfaces. Metal fabricators and welders constitute a significant customer segment, utilizing angle grinders for deburring, shaping, and finishing metal components in workshops and manufacturing facilities. Automotive technicians and body repair specialists also represent a crucial customer base, employing grinders for rust removal, panel cutting, and preparing surfaces for painting. Beyond these traditional industrial applications, a substantial portion of the market is driven by DIY enthusiasts and homeowners engaged in renovation, repair, or creative projects, seeking versatile and accessible tools for tasks such as cutting tiles, sanding wood, or removing old mortar. Furthermore, general maintenance personnel across various industries, from facility management to agriculture, frequently use angle grinders for routine equipment upkeep and repairs. The purchasing decisions of these diverse customers are influenced by factors such as tool power, durability, safety features, brand reputation, price point, and the availability of accessories. Professionals typically prioritize high performance, robust build quality, and ergonomic designs for extended use, often investing in premium, feature-rich models. Conversely, DIY consumers may opt for more budget-friendly, user-friendly options that balance functionality with ease of handling. Manufacturers strategically segment their product lines and marketing efforts to effectively address the specific requirements and buying behaviors of each of these distinct customer groups, ensuring comprehensive market coverage and sustained demand across all user categories.

Angle grinder Market Key Technology Landscape

The Angle grinder Market is continuously evolving, driven by significant advancements in its underlying technology landscape, which aims to enhance performance, safety, and user experience. A pivotal technological shift has been the widespread adoption of brushless motors. Unlike traditional brushed motors, brushless variants offer superior efficiency, generate less heat, have a longer operational lifespan due to the absence of wear-and-tear components like carbon brushes, and provide more consistent power delivery, which is critical for demanding tasks. Concurrently, advancements in lithium-ion battery technology have revolutionized the cordless angle grinder segment, dramatically increasing run-time, reducing charge times, and improving power output, allowing cordless tools to rival the performance of their corded counterparts. Ergonomic design principles are increasingly integrated, focusing on anti-vibration systems and improved handle geometries to minimize user fatigue and enhance control, particularly during prolonged use. Safety features have seen substantial innovation, including electronic kickback protection, which instantly shuts off the tool if the disc binds, reducing the risk of injury. Restart protection prevents accidental startup after a power interruption, and rapid braking systems ensure the disc stops quickly once the trigger is released. Tool-free disc change mechanisms simplify and expedite accessory replacement, while dust extraction systems are becoming more sophisticated, improving air quality and extending tool life in dusty environments. Furthermore, a nascent but growing trend involves the incorporation of smart connectivity, leveraging IoT technology to enable features such as tool tracking, remote diagnostics, usage data logging, and even theft deterrence, offering unprecedented levels of asset management and predictive maintenance for professional users. These technological innovations collectively contribute to a more powerful, safer, and user-friendly angle grinder, continuously expanding its utility and market appeal across various applications and end-user segments.

Regional Highlights

- Asia-Pacific: Dominates the market due to robust construction activities, rapid industrialization, and significant infrastructure development in countries like China, India, and Southeast Asian nations. High population density and expanding manufacturing sectors drive consistent demand for power tools.

- North America: A mature market characterized by a strong demand for high-performance, professional-grade tools. Focus on safety standards, advanced features, and a growing DIY culture contribute to steady market growth.

- Europe: Exhibits stable growth with a strong emphasis on ergonomic design, environmental regulations, and advanced safety features. Germany, the UK, and France are key contributors, driven by manufacturing and construction sectors.

- Latin America: An emerging market experiencing growth due to increasing urbanization, public infrastructure projects, and a burgeoning industrial base. Brazil and Mexico are significant markets within this region.

- Middle East & Africa: Shows promising growth fueled by large-scale construction and energy projects, particularly in the GCC countries, alongside developing industrial sectors seeking reliable power tool solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Angle grinder Market.- Robert Bosch GmbH (Germany)

- Stanley Black & Decker, Inc. (USA)

- Makita Corporation (Japan)

- Hilti Corporation (Liechtenstein)

- Techtronic Industries Co. Ltd. (Milwaukee Tool, Ryobi) (Hong Kong)

- Metabo (Koki Holdings Co., Ltd.) (Germany)

- Apex Tool Group, LLC (USA)

- DEWALT (Stanley Black & Decker brand) (USA)

- Hitachi Koki (Koki Holdings Co., Ltd.) (Japan)

- Positec Tool Corporation (WORX, Rockwell) (China)

Frequently Asked Questions

What are the primary applications of an angle grinder?

Angle grinders are versatile tools primarily used for cutting, grinding, and polishing various materials such as metal, stone, concrete, and tile. They are indispensable in construction, metal fabrication, automotive repair, and extensive DIY projects.

What is the main difference between corded and cordless angle grinders?

Corded angle grinders offer continuous power for heavy-duty, prolonged tasks without battery limitations, ideal for workshops. Cordless versions provide superior mobility and flexibility, powered by rechargeable batteries, making them perfect for remote job sites or areas without immediate power access.

What safety features should I look for in an angle grinder?

Key safety features include kickback protection (automatic shut-off if the disc binds), restart protection (prevents accidental startup after power loss), rapid braking systems (stops the disc quickly), and anti-vibration handles to reduce fatigue and enhance control.

How is technology impacting the angle grinder market?

Technological advancements are driving the market through innovations like brushless motors for efficiency and longevity, improved lithium-ion batteries for cordless performance, enhanced ergonomic designs for user comfort, and smart features for predictive maintenance and asset tracking.

What factors are driving the growth of the angle grinder market?

Market growth is propelled by global infrastructure development, industrialization in emerging economies, increasing participation in DIY and home improvement projects, and continuous technological improvements that enhance tool performance, safety, and versatility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Power Angle Grinder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Angle Grinder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Variable Speed Angle Grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Angle Grinder Market Statistics 2025 Analysis By Application (Metal Processing, Wood Processing, Construction), By Type (Electric Angle Grinder, Pneumatic Angle Grinder), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager