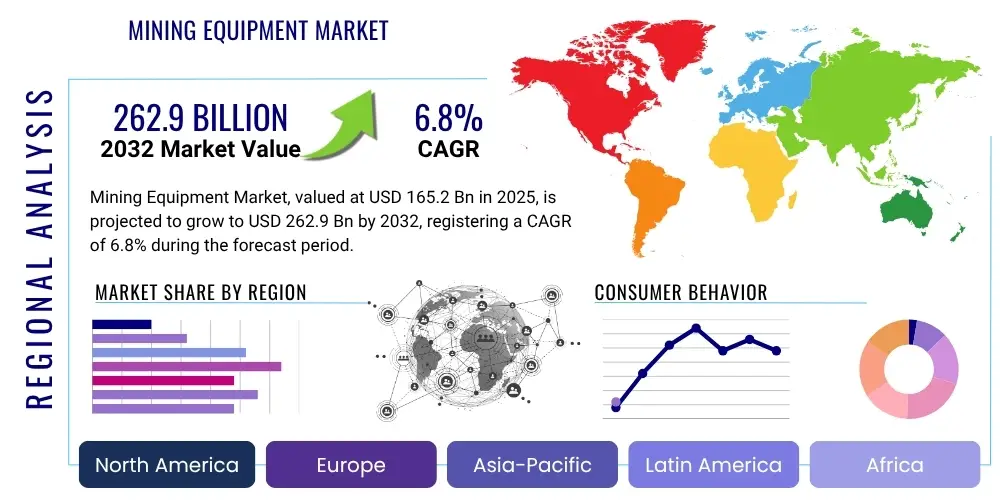

Mining Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430417 | Date : Nov, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Mining Equipment Market Size

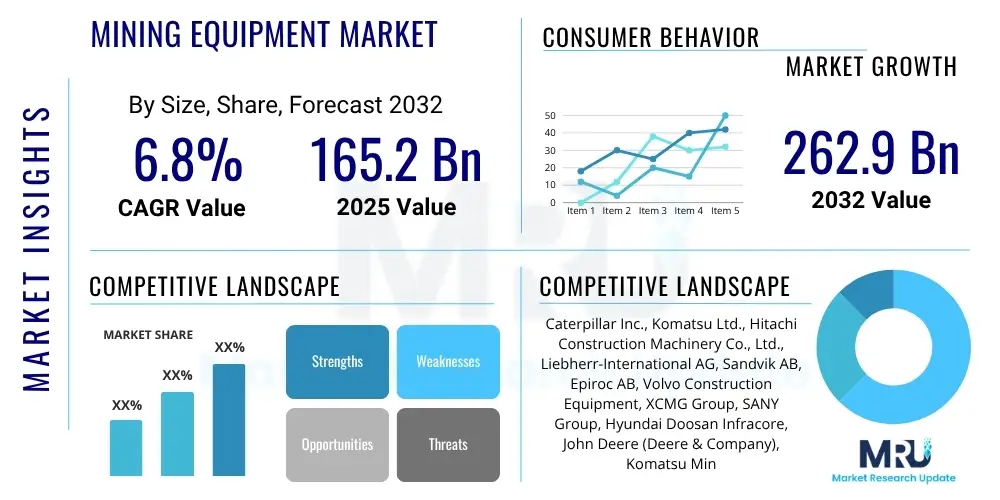

The Mining Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $165.2 Billion in 2025 and is projected to reach $262.9 Billion by the end of the forecast period in 2032.

Mining Equipment Market introduction

The Mining Equipment Market encompasses a broad range of heavy machinery and advanced technological solutions utilized for the extraction, loading, hauling, and processing of minerals, metals, and coal from the earth. These robust machines are engineered to operate in some of the harshest environments, providing the necessary power, precision, and durability for both surface and underground mining operations. The primary objective of these products is to enhance productivity, improve safety standards for personnel, and optimize operational costs across various stages of the mining lifecycle.

Major applications for mining equipment span across diverse sectors including coal mining, metal mining (such as iron ore, copper, gold, bauxite), and mineral mining (industrial minerals, diamonds, phosphates, potash). The continuous global demand for raw materials, driven by rapid industrialization, urbanization, and infrastructure development, underpins the market's significance. Mining equipment plays a crucial role in supplying the foundational resources essential for modern economies, from construction materials to components for electronics and energy technologies.

The key benefits derived from modern mining equipment include increased operational efficiency through higher throughput and reduced downtime, enhanced worker safety via automation and remote operation capabilities, and a lower environmental footprint through more fuel-efficient and electrically powered machinery. Driving factors for market growth include escalating global demand for minerals and metals, significant technological advancements in automation and digitalization, and a renewed focus on exploration activities in new and existing reserves. These elements collectively shape the trajectory and innovation landscape of the mining equipment industry.

Mining Equipment Market Executive Summary

The Mining Equipment Market is experiencing dynamic shifts, characterized by several key business trends including a strong emphasis on automation, digitalization, and electrification to boost productivity and reduce operational costs. Mining companies are increasingly investing in smart equipment that integrates IoT, AI, and data analytics for predictive maintenance, real-time monitoring, and optimized resource utilization. This digital transformation is not only enhancing efficiency but also addressing safety concerns and environmental compliance pressures across the industry. The drive towards sustainable mining practices is also compelling manufacturers to develop more energy-efficient and low-emission machinery, including battery-electric vehicles (BEVs) for underground operations.

Regionally, the market exhibits varied growth patterns. Asia Pacific stands out as the fastest-growing region, fueled by robust industrial development, infrastructure projects, and significant mineral resource extraction activities in countries like China, India, and Australia. North America and Europe, while mature markets, are leading in the adoption of advanced technologies such as autonomous equipment and digital solutions, driven by innovation, stringent safety regulations, and a focus on operational excellence. Latin America and the Middle East and Africa regions represent significant opportunities due to abundant untapped mineral reserves and increasing foreign investments in mining projects, though they face challenges related to political stability and infrastructure development.

Segmentation trends indicate a growing preference for surface mining equipment due to its cost-effectiveness for large-scale operations, although underground mining equipment is seeing innovation to tackle deeper, more complex reserves. Product-wise, hauling equipment, excavators, and drilling machines continue to dominate, with an increasing demand for specialized processing equipment that can handle diverse ore types efficiently. The application segments for metal and mineral mining are projected to grow significantly, spurred by the electric vehicle revolution and demand for critical minerals. Furthermore, technology-driven segments, particularly autonomous and electrified equipment, are poised for substantial expansion, reflecting the industry's commitment to modernization and sustainability.

AI Impact Analysis on Mining Equipment Market

User questions related to the impact of AI on the Mining Equipment Market frequently revolve around how AI can enhance operational efficiency, improve safety, and reduce costs. Common inquiries also touch upon the practical applications of AI in predictive maintenance, autonomous operations, and geological data analysis, alongside concerns regarding job displacement and the technical skills required for implementation. There is a clear interest in understanding the tangible benefits of AI, such as optimized material flow and energy consumption, while also acknowledging the challenges of integrating complex AI systems into existing infrastructure and ensuring data security. The overarching theme is the pursuit of smarter, safer, and more sustainable mining through artificial intelligence, balanced with a realistic assessment of its deployment complexities.

- Enhanced predictive maintenance and equipment diagnostics, reducing unplanned downtime.

- Optimization of drilling, blasting, and material handling processes through real-time data analysis.

- Facilitation of autonomous and semi-autonomous vehicle operation, improving safety and productivity.

- Advanced geological modeling and resource estimation, leading to more precise extraction strategies.

- Improved safety monitoring by identifying potential hazards and ensuring compliance with operational protocols.

- Real-time monitoring of energy consumption, optimizing power usage for heavy machinery.

- Automation of repetitive or hazardous tasks, allowing human operators to focus on strategic oversight.

- Supply chain optimization and inventory management for spare parts and consumables.

- Development of smart sensors and IoT devices that feed data for AI-driven insights.

- Enhanced environmental monitoring and compliance reporting using AI to analyze vast datasets.

DRO & Impact Forces Of Mining Equipment Market

The Mining Equipment Market is significantly influenced by a confluence of drivers, restraints, opportunities, and external impact forces. Global demand for minerals and metals, propelled by rapid urbanization, industrialization, and infrastructure development, stands as a primary driver. The transition towards green energy technologies, such as electric vehicles and renewable energy infrastructure, further fuels the demand for critical minerals like copper, lithium, and cobalt, thereby necessitating more efficient and advanced mining equipment. Technological advancements in automation, digitalization, and electrification also serve as strong drivers, pushing manufacturers to innovate and mining companies to upgrade their fleets for improved productivity and safety.

Conversely, several factors act as restraints on market growth. Stringent environmental regulations and social license to operate concerns often delay or halt mining projects, increasing operational complexities and costs. The inherently high capital expenditure required for purchasing and maintaining mining equipment can be a significant barrier, particularly for smaller mining firms. Furthermore, the volatility of commodity prices directly impacts the profitability of mining operations, influencing investment decisions in new machinery. A shortage of skilled labor capable of operating and maintaining advanced equipment also presents a substantial challenge to market expansion and efficiency.

Despite these restraints, significant opportunities exist within the market. The ongoing trend towards automation and remote-controlled operations presents avenues for enhancing safety, reducing labor costs, and improving operational continuity in challenging environments. The increasing adoption of electrification, particularly for underground mining equipment, promises to reduce emissions and improve air quality in enclosed spaces. Moreover, the development of sustainable mining practices, including advanced waste management and water recycling technologies, offers growth potential for equipment providers focusing on environmental solutions. Impact forces such as geopolitical stability, global economic health, and trade policies also play a critical role, influencing investment flows and the overall trajectory of the mining sector and its equipment market.

Segmentation Analysis

The Mining Equipment Market is segmented based on various factors, including the type of mining operation, the specific product category, the application area, and the technological sophistication of the equipment. This multi-faceted segmentation helps to understand the diverse demands and preferences across the global mining industry. Each segment represents distinct operational requirements and growth trajectories, shaped by geographical geology, regulatory landscapes, and the economic viability of extracting different resources. Analyzing these segments provides a granular view of market dynamics and aids in strategic planning for both equipment manufacturers and mining companies.

- By Type

- Surface Mining Equipment: Includes large-scale machinery used in open-pit or strip mining operations, such as draglines, hydraulic excavators, and large haul trucks.

- Underground Mining Equipment: Comprises specialized machinery designed for confined spaces, including continuous miners, shuttle cars, roof bolters, LHDs (Load-Haul-Dump machines), and narrow vein drills.

- By Product

- Excavators: Hydraulic excavators, electric rope shovels, and front-end loaders used for digging and loading overburden and ore.

- Loaders: Wheel loaders, track loaders, and skid-steer loaders for material handling and stockpiling.

- Dozers: Track dozers and wheel dozers for pushing, ripping, and grading materials.

- Drills & Breakers: Rotary drills, percussion drills, jumbo drills, and rock breakers for blasting and breaking hard rock.

- Crushers & Grinding Mills: Jaw crushers, cone crushers, gyratory crushers, ball mills, and sag mills for primary, secondary, and tertiary crushing and grinding of ore.

- Hauling Equipment: Off-highway dump trucks, articulated dump trucks, conveyors, and rail systems for transporting ore and waste materials.

- Mineral Processing Equipment: Flotation cells, thickeners, filters, magnetic separators, and screens used in the beneficiation of raw ore.

- Other Equipment: Pumps, ventilation systems, support equipment, and safety systems.

- By Application

- Coal Mining: Equipment specifically adapted for the extraction of coal, considering seam thickness and geological conditions.

- Metal Mining: Machinery used for mining various metals, including iron ore, copper, gold, silver, bauxite, nickel, and zinc.

- Mineral Mining: Equipment for extracting industrial minerals, diamonds, phosphates, potash, and other non-metallic minerals.

- By Technology

- Autonomous Equipment: Self-driving haul trucks, drills, and loaders controlled remotely or by AI systems.

- Electrified Equipment: Battery-electric vehicles (BEVs) and other electric-powered machinery aimed at reducing emissions and improving efficiency.

- Digitally Integrated Equipment: Machinery featuring advanced sensors, IoT connectivity, and data analytics capabilities for real-time monitoring and optimization.

Value Chain Analysis For Mining Equipment Market

The value chain of the Mining Equipment Market is a complex network involving multiple stages, from raw material sourcing to the end-user deployment and aftermarket services. The upstream segment of the value chain is critical, encompassing the procurement of diverse raw materials such as specialized steels, alloys, hydraulic components, advanced electronics, and composite materials. Manufacturers rely heavily on a robust supply chain for high-quality, durable components that can withstand the extreme conditions of mining operations. This stage also includes research and development, where significant investments are made in designing innovative and technologically advanced equipment, focusing on efficiency, safety, and environmental impact.

Moving downstream, the value chain involves the manufacturing, assembly, and testing of the equipment. Original Equipment Manufacturers (OEMs) play a central role, utilizing advanced manufacturing processes and stringent quality control to produce reliable machinery. Once manufactured, the equipment reaches the end-users—mining companies and contractors—through various distribution channels. These channels include direct sales by the OEM, where large mining corporations often negotiate directly for customized solutions and comprehensive service packages. Alternatively, a vast network of authorized dealers and distributors facilitates indirect sales, providing localized sales support, spare parts, and maintenance services, especially to smaller and medium-sized mining operations.

The direct distribution channel is typically characterized by high-value, large-volume sales to major mining corporations, often involving bespoke solutions, long-term service agreements, and direct technical support from the manufacturer. This approach fosters strong relationships and allows for tailored product development. The indirect channel, on the other hand, leverages regional expertise and extensive reach, making equipment accessible to a wider range of customers and ensuring timely delivery of parts and services. Both channels are vital for market penetration and customer satisfaction, with aftermarket services like maintenance, repairs, parts supply, and technology upgrades forming a significant revenue stream and a crucial aspect of customer retention throughout the equipment's operational lifespan. This entire chain is supported by robust logistics and sophisticated financial services, enabling the global trade and financing of high-value mining assets.

Mining Equipment Market Potential Customers

Potential customers for the Mining Equipment Market primarily consist of a diverse array of entities involved in the extraction and processing of mineral resources worldwide. At the forefront are large-scale, multinational mining corporations, which operate across multiple geographies and commodities. These companies often possess substantial capital for investment in advanced, high-capacity machinery, frequently opting for integrated solutions that include automation, remote operation capabilities, and comprehensive service contracts. Their purchasing decisions are driven by the need for economies of scale, operational efficiency, safety compliance, and technological leadership to maintain a competitive edge in global commodity markets.

Beyond the major players, the market also serves numerous small-to-mid-sized mining firms. These companies typically operate regional or smaller-scale projects and may have more constrained budgets, leading them to seek cost-effective, durable, and versatile equipment. They often rely heavily on local distributors for sales, support, and aftermarket services, valuing reliability, ease of maintenance, and readily available spare parts. Their purchasing motivations are often centered on maximizing return on investment from specific, less capital-intensive mining ventures, requiring a balance between performance and affordability.

Furthermore, government-owned mining entities, independent mining contractors, and quarrying operations also represent significant customer segments. Government entities might focus on strategic resource extraction for national development, while contractors provide specialized mining services to various clients, requiring flexible and robust fleets. Quarrying operations, engaged in extracting aggregates and construction materials, often demand specific types of crushing, screening, and hauling equipment. Each customer segment presents unique requirements in terms of equipment type, technological sophistication, service expectations, and purchasing power, necessitating a tailored approach from equipment manufacturers and suppliers to address their distinct operational challenges and strategic objectives effectively.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $165.2 Billion |

| Market Forecast in 2032 | $262.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Caterpillar Inc., Komatsu Ltd., Hitachi Construction Machinery Co., Ltd., Liebherr-International AG, Sandvik AB, Epiroc AB, Volvo Construction Equipment, XCMG Group, SANY Group, Hyundai Doosan Infracore, John Deere (Deere & Company), Komatsu Mining Corp., Metso Outotec, ThyssenKrupp AG, FLSmidth & Co. A/S, CNH Industrial N.V., Atlas Copco, Weichai Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Mining Equipment Market Key Technology Landscape

The Mining Equipment Market is currently experiencing a profound technological transformation, driven by the imperative to enhance safety, improve efficiency, and reduce environmental impact. Key technologies shaping this landscape include advanced automation and autonomous systems. Autonomous haulage systems, drills, and loaders are becoming increasingly prevalent, especially in large-scale surface mining operations. These systems leverage GPS, LiDAR, radar, and sophisticated algorithms to navigate, operate, and perform tasks with minimal human intervention, thereby reducing operational risks and increasing productivity around the clock. The integration of artificial intelligence and machine learning is further optimizing these autonomous operations, allowing for real-time decision-making, predictive maintenance, and adaptive resource allocation.

Another pivotal area of innovation is the electrification of mining equipment. With growing environmental concerns and a focus on reducing carbon emissions, battery-electric vehicles (BEVs) are gaining significant traction, particularly for underground mining. Electric equipment eliminates exhaust fumes, improving air quality in enclosed environments, and often offers lower operating costs due due to reduced fuel consumption and maintenance. Alongside electrification, the Internet of Things (IoT) plays a crucial role, with an array of sensors embedded in machinery collecting vast amounts of data on performance, health, and operational parameters. This data is transmitted to centralized control rooms for real-time monitoring and analysis, enabling proactive maintenance and operational adjustments.

Furthermore, remote operation centers are becoming standard, allowing operators to control multiple machines from a safe, comfortable, and centralized location, often thousands of miles away from the mine site. This not only mitigates risks associated with hazardous environments but also enables a more efficient utilization of skilled personnel. Data analytics platforms, digital twinning, and virtual reality (VR) and augmented reality (AR) are also emerging as essential tools for planning, training, and troubleshooting, providing immersive experiences and predictive capabilities. These technologies collectively contribute to a smarter, safer, and more sustainable mining industry, profoundly changing the way resources are extracted and processed globally.

Regional Highlights

- North America: A mature market characterized by significant investments in technological innovation, including autonomous mining solutions, digitalization, and electrification. The region benefits from stringent safety regulations and a strong focus on operational efficiency. Countries like the United States and Canada are leaders in adopting advanced mining practices, particularly in metal and industrial mineral extraction.

- Europe: Driven by a strong emphasis on environmental sustainability and workplace safety, Europe is at the forefront of developing green mining technologies, including low-emission and electric equipment. Countries like Sweden and Finland are notable for their highly automated and innovative underground mining operations, focusing on critical raw materials for the automotive and electronics industries.

- Asia Pacific (APAC): The largest and fastest-growing market, fueled by robust industrialization, rapid urbanization, and extensive infrastructure development, particularly in China, India, and Australia. This region is a major consumer and producer of coal, iron ore, and other base metals, leading to high demand for both surface and underground mining equipment. Significant investments in new mining projects and upgrading existing ones are driving market expansion.

- Latin America: A resource-rich region with substantial reserves of copper, iron ore, gold, and silver, making it a critical market for heavy mining equipment. Countries like Chile, Peru, and Brazil are key players. The market growth here is often influenced by global commodity prices and foreign investments, with an increasing focus on improving productivity and safety standards.

- Middle East and Africa (MEA): An emerging market with vast untapped mineral resources, including gold, diamonds, phosphates, and bauxite. While still developing, the region presents significant growth opportunities, driven by increasing exploration activities and government initiatives to diversify economies beyond oil. Challenges include political instability and infrastructure development, but long-term prospects are promising with increasing foreign direct investment in the mining sector.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Mining Equipment Market.- Caterpillar Inc.

- Komatsu Ltd.

- Hitachi Construction Machinery Co., Ltd.

- Liebherr-International AG

- Sandvik AB

- Epiroc AB

- Volvo Construction Equipment

- XCMG Group

- SANY Group

- Hyundai Doosan Infracore

- John Deere (Deere & Company)

- Komatsu Mining Corp. (formerly Joy Global Inc.)

- Metso Outotec

- ThyssenKrupp AG

- FLSmidth & Co. A/S

- CNH Industrial N.V.

- Atlas Copco

- Weichai Group

Frequently Asked Questions

What are the primary factors driving growth in the Mining Equipment Market?

Growth is primarily driven by escalating global demand for minerals and metals due to industrialization, urbanization, and infrastructure development, alongside significant technological advancements in automation, digitalization, and the push towards sustainable, electrified mining operations.

How is AI impacting the Mining Equipment Market?

AI is transforming the market by enabling advanced predictive maintenance, optimizing operational processes, facilitating autonomous vehicle deployment for enhanced safety and productivity, and improving geological modeling for more precise resource extraction.

What are the key challenges faced by the Mining Equipment Market?

Key challenges include stringent environmental regulations, high capital expenditure requirements for advanced machinery, volatility in commodity prices affecting investment, and a persistent shortage of skilled labor for operating and maintaining complex equipment.

Which geographical region holds the largest share in the Mining Equipment Market?

The Asia Pacific (APAC) region currently holds the largest market share, driven by rapid industrial expansion, extensive infrastructure projects, and significant mineral extraction activities in major economies like China, India, and Australia.

What are the emerging technological trends in mining equipment?

Emerging trends include widespread adoption of autonomous mining equipment, electrification of fleets (especially for underground operations), integration of IoT and advanced sensors for real-time data, and the deployment of remote operation centers for enhanced safety and efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Surface Mining Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Mining Equipment Tire Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Underground Mining Equipment and Service Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Mining Equipment Market Size Report By Type (Underground Mining Equipment, Surface Mining Equipment, Crushing, Pulverizing & Screening Equipment, Drills & Breakers, Others), By Application (Metal Mining, Non-metal Mining, Coal Mining), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Electrical Computer Aided Design Market Size Report By Type (Software, Services), By Application (Industrial Machine Controls, Plant Design, Mining Equipment Control, Rail Signaling, Switchgear Design, Water Treatment and Distribution System Control, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager