Styrene Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443558 | Date : Feb, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Styrene Market Size

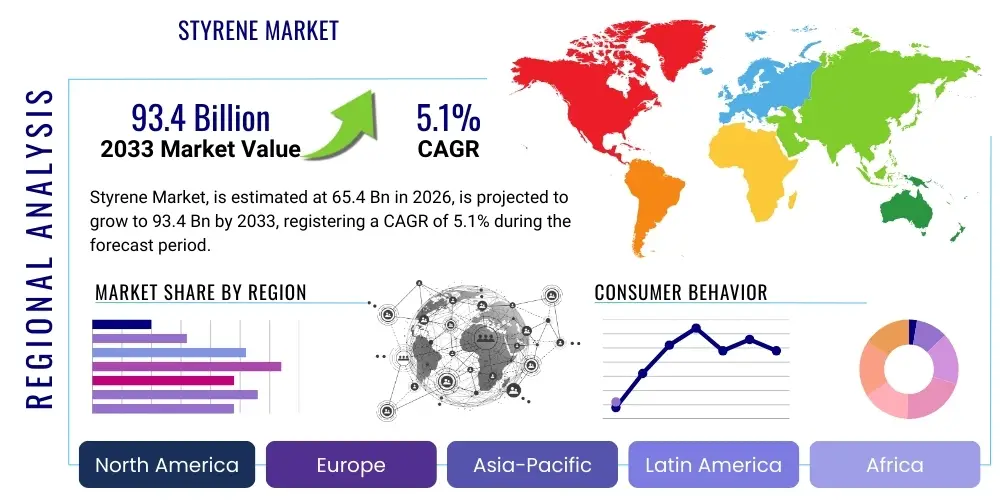

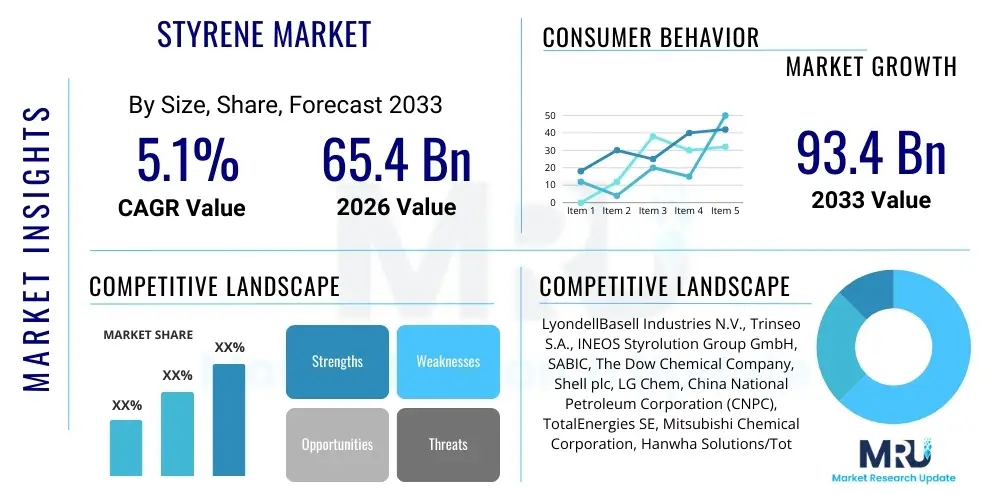

The Styrene Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.1% between 2026 and 2033. The market is estimated at USD 65.4 Billion in 2026 and is projected to reach USD 93.4 Billion by the end of the forecast period in 2033. This consistent growth trajectory is fundamentally driven by the escalating demand for high-performance plastics and elastomers across critical end-use sectors, particularly in the construction and packaging industries, especially within rapidly industrializing economies of the Asia Pacific region. The maturity of polymerization technologies and the relatively stable, large-scale production capacities globally support this expansion, although volatility in raw material pricing presents a persistent challenge.

Styrene Market introduction

Styrene, chemically known as vinylbenzene, is a crucial aromatic monomer characterized by its ability to readily polymerize, making it an indispensable building block for a vast range of synthetic materials. It is derived primarily from ethylbenzene, which itself is produced from benzene and ethylene feedstocks. The resulting polymer, polystyrene (PS), is the single largest application for styrene, yielding durable and lightweight materials utilized extensively in insulation, food packaging, and consumer goods. Beyond polystyrene, styrene is vital for the production of Acrylonitrile Butadiene Styrene (ABS), Styrene-Butadiene Rubber (SBR), and Unsaturated Polyester Resins (UPR), each serving distinct, high-value applications.

The primary benefits of styrene derivatives include superior impact resistance, excellent thermal insulation properties, light weight, and cost-effectiveness in mass production. These attributes make styrene-based products essential for automotive components aimed at weight reduction and fuel efficiency, construction materials requiring energy conservation, and robust packaging solutions needed for supply chain logistics. Key driving factors underpinning market growth include the booming global construction industry, particularly the demand for Expanded Polystyrene (EPS) used in insulation systems, and the relentless expansion of the e-commerce sector which relies heavily on protective and durable packaging materials.

Furthermore, the automotive industry's push for lightweight vehicle construction to meet stringent emission standards fuels the demand for ABS and specialized styrene polymers. While the market faces headwinds regarding sustainability and regulatory scrutiny over the use of plastics, innovation in chemical recycling technologies and the development of bio-based styrene alternatives offer significant future growth avenues, solidifying the monomer's foundational role in the petrochemical landscape.

Styrene Market Executive Summary

The global Styrene market exhibits dynamic business trends characterized by intense geographic shifts in production and consumption, coupled with significant investments in capacity expansion, predominantly within Northeast Asia and the Middle East. Business trends highlight a focus on integrating derivative production, enabling manufacturers to capture greater value across the chain and mitigate risks associated with raw material price volatility. Key industry players are increasingly prioritizing efficiency enhancements in conventional production processes—such as ethylbenzene dehydrogenation—and exploring cleaner, less energy-intensive technologies, partially in response to mounting global environmental compliance requirements and the long-term goal of carbon footprint reduction.

Regional trends unequivocally underscore the Asia Pacific region, led by China and India, as the definitive epicenter of both demand and production capacity for styrene monomer, fueled by exponential growth in domestic construction, appliance manufacturing, and packaging demands. North America and Europe, while representing mature markets, maintain crucial roles as innovation hubs, focusing less on commodity production and more on specialty derivatives like styrene-butadiene latexes for high-end coatings and adhesives, and advanced recycling methodologies. Conversely, the Middle East is capitalizing on low-cost natural gas feedstock to expand its petrochemical base, positioning itself as a major export hub for commodity styrene monomer, influencing global trade flows and pricing mechanisms.

Segment trends demonstrate the persistent dominance of polystyrene (PS)—including General Purpose Polystyrene (GPPS) and High Impact Polystyrene (HIPS)—as the primary application, though the fastest growth is often observed in specialty segments like Acrylonitrile Butadiene Styrene (ABS) and Styrene-Butadiene Rubber (SBR). ABS demand is surging due to its crucial role in consumer electronics and automotive dashboards, while SBR remains essential for tire manufacturing and asphalt modification. Sustainability mandates are accelerating the adoption of EPS in building insulation, driving segment growth focused on energy efficiency, while the nascent segment of bio-based styrene, though small, signals future investment redirection towards circular economy models.

AI Impact Analysis on Styrene Market

Analysis of common user questions related to the impact of Artificial Intelligence (AI) on the Styrene Market reveals a high degree of interest centered around operational efficiency, risk mitigation, and sustainable production. Users frequently ask: "How can AI optimize the energy consumption in styrene production?", "Can predictive maintenance driven by AI prevent unplanned shutdowns in petrochemical plants?", and "What is the role of machine learning in forecasting volatile feedstock prices (benzene and ethylene)?" These inquiries underscore user expectations for AI to solve persistent challenges related to high operating costs, complex reaction control, and supply chain vulnerability inherent in large-scale chemical manufacturing.

The key themes emerging from this analysis include a strong emphasis on leveraging AI for prescriptive analytics in manufacturing processes. Specifically, AI is expected to revolutionize catalyst performance monitoring and reaction condition optimization (temperature, pressure, residence time) in the ethylbenzene dehydrogenation stage, thereby maximizing yield and minimizing energy intensity. Furthermore, users anticipate that advanced machine learning models will significantly enhance safety protocols by predicting equipment failure hours or days in advance, translating directly into reduced maintenance expenditures and maximized uptime, which is critical given the high capital intensity of styrene production facilities.

Ultimately, the core expectation is that AI will transform styrene manufacturing from a historically reactive operational model to a highly predictive and autonomous system. This transition is not only expected to deliver substantial financial benefits through efficiency gains but also to support sustainability goals by identifying optimal operational windows that reduce byproduct formation and enhance material flow throughout the entire complex supply chain, from feedstock procurement to derivative polymer distribution.

- AI-driven predictive maintenance reduces unplanned downtime and catastrophic failure risks in polymerization reactors.

- Machine learning algorithms optimize reaction parameters (temperature, flow rate) to increase styrene yield and purity.

- Advanced analytics improves feedstock price forecasting, enabling proactive procurement strategies for benzene and ethylene.

- AI enhances energy management systems, minimizing utility consumption in energy-intensive dehydrogenation processes.

- Vision systems coupled with AI improve quality control and defect detection in downstream polymer processing (e.g., PS pellet inspection).

- Generative AI supports R&D efforts in designing novel catalysts and optimizing sustainable production pathways like bio-styrene synthesis.

DRO & Impact Forces Of Styrene Market

The dynamics of the Styrene market are governed by a complex interplay of drivers, restraints, and opportunities (DRO), which collectively constitute the primary impact forces shaping its trajectory. The fundamental driver remains the robust and growing demand from end-use sectors, particularly packaging and construction, propelled by global population growth and urbanization. The inherent versatility of styrene derivatives, allowing for customized physical properties tailored to diverse applications—from lightweight automotive parts (ABS) to highly insulating building materials (EPS)—ensures sustained market penetration. Furthermore, economic prosperity in developing nations directly correlates with increased consumption of durable goods and improved infrastructure, acting as a major, enduring market driver.

However, the market is significantly restrained by the highly volatile pricing and availability of its primary feedstocks: benzene and ethylene. As petroleum derivatives, their costs fluctuate sharply with crude oil prices and geopolitical instability, directly impacting the profitability margins of styrene producers. Additionally, stringent environmental regulations in North America and Europe concerning volatile organic compound (VOC) emissions from styrene usage, coupled with pervasive public and regulatory pressure to reduce the consumption of single-use plastics, impose significant operational and developmental constraints on the industry. The perceived health risks associated with residual styrene in certain applications also necessitate continuous monitoring and technological mitigation, adding complexity to production.

Conversely, significant opportunities exist, most notably in the development and commercialization of bio-based styrene (B-SM) derived from renewable sources like lignocellulosic biomass, offering a pathway to decouple production from fossil fuels. Investment in chemical recycling technologies—focused on depolymerizing polystyrene back into recoverable styrene monomer—represents another critical opportunity, aligning the industry with circular economy principles and potentially alleviating waste management issues. These opportunities, driven by technological innovation and sustainability mandates, are key impact forces positioning the market for long-term resilience and growth beyond traditional petrochemical cycles.

Segmentation Analysis

The global Styrene market is systematically segmented based on derivative type, application, and end-use industry, reflecting the diverse utilization profile of the monomer. This comprehensive segmentation allows market participants to accurately gauge demand trends and tailor production strategies toward high-growth niches. Polystyrene remains the largest segment, characterized by high-volume commodity production, but other segments, such as Acrylonitrile Butadiene Styrene (ABS) and Styrene-Butadiene Rubber (SBR), command premium pricing and demonstrate faster growth rates due to their utilization in high-performance engineering applications and specialized elastomers. Analyzing these segments is critical for understanding regional disparities in industrial focus.

Segmentation by application reveals a critical reliance on the material's structural and insulating properties. Packaging, particularly food and protective packaging, is the undisputed dominant application, primarily utilizing General Purpose Polystyrene (GPPS) and Expanded Polystyrene (EPS). However, the long-term, high-value growth is often concentrated in construction, where EPS provides essential thermal insulation for energy-efficient buildings, and in the automotive sector, where ABS and specialty polymers contribute to vehicle lightweighting and interior durability. The healthcare and electronics sectors also represent increasingly important, though smaller, high-specification segments demanding exceptionally pure grades of styrene derivatives.

- By Derivative Type:

- Polystyrene (PS)

- General Purpose Polystyrene (GPPS)

- High Impact Polystyrene (HIPS)

- Expanded Polystyrene (EPS)

- Acrylonitrile Butadiene Styrene (ABS)

- Styrene-Acrylonitrile (SAN)

- Styrene-Butadiene Rubber (SBR)

- Unsaturated Polyester Resins (UPR)

- Styrene Butadiene Latex (SBL)

- Others (e.g., SM/PO, speciality copolymers)

- Polystyrene (PS)

- By Application:

- Packaging (Food packaging, protective foams)

- Construction (Insulation, piping)

- Automotive (Interior/exterior parts, tires)

- Consumer Goods and Appliances

- Electronics

- Adhesives, Coatings, and Latex

Value Chain Analysis For Styrene Market

The Styrene value chain is characterized by high integration and capital intensity, beginning with the upstream supply of fundamental petrochemical feedstocks. The primary upstream components are crude oil and natural gas, which are processed into benzene and ethylene. Benzene is typically sourced from reformate or pyrolysis gasoline, while ethylene is derived from steam cracking. The strong correlation between the price volatility of these commodities and the final cost of styrene monomer necessitates sophisticated risk management and long-term supply agreements for major producers. Integrated petrochemical complexes benefit significantly by capturing cost efficiencies across these initial stages.

The midstream stage involves the highly technical production of styrene monomer itself, typically via the alkylation of benzene with ethylene to form ethylbenzene, followed by the catalytic dehydrogenation of ethylbenzene to styrene. This process requires vast energy consumption and highly specialized catalytic systems. Major global manufacturers operate large-scale, continuous production facilities to benefit from economies of scale. The effectiveness of the midstream operation dictates the purity and cost competitiveness of the bulk monomer supplied to the global market, positioning large-capacity producers in Asia and the Middle East advantageously.

The downstream segment encompasses the polymerization of styrene monomer into its various derivatives, including commodity plastics (PS, EPS, GPPS, HIPS) and engineering plastics (ABS, SAN, SBR). These derivatives are then sold through direct and indirect distribution channels to a wide array of end-use sectors. Direct sales are common for large volume buyers in the automotive and major construction projects, while indirect distribution, leveraging chemical distributors and specialized compounders, serves fragmented markets like specialized adhesives or smaller consumer goods manufacturers. The efficiency of the logistics network—including bulk liquid shipping and storage of monomers, and palletized distribution of polymers—is paramount for maintaining competitiveness and minimizing supply lag.

Styrene Market Potential Customers

The potential customers for styrene monomer are overwhelmingly large-scale industrial consumers engaged in the manufacturing of derivatives and end-products, defined by high-volume consumption across various sectors. The most significant customer base comprises polymer producers that specialize in transforming styrene into polystyrene (PS) resins, which are then sold for packaging and insulation applications. These customers require continuous, high-purity supply delivered via specialized logistics. Another crucial segment includes manufacturers of engineering plastics, specifically those producing Acrylonitrile Butadiene Styrene (ABS) and Styrene-Acrylonitrile (SAN), whose products serve the exacting requirements of the automotive and consumer electronics industries.

Furthermore, the textile and construction industries represent a substantial group of end-users for derivatives. Construction companies rely heavily on manufacturers of Expanded Polystyrene (EPS) for thermal insulation panels and geofoam applications, demanding products that meet strict building codes for fire resistance and energy efficiency. The tire and footwear industries are major consumers of Styrene-Butadiene Rubber (SBR), requiring a consistent supply of SBR producers to ensure the quality and durability of their rubber products. These varied customer groups necessitate different grade specifications, demanding flexibility and customization from the styrene market suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 65.4 Billion |

| Market Forecast in 2033 | USD 93.4 Billion |

| Growth Rate | 5.1% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | LyondellBasell Industries N.V., Trinseo S.A., INEOS Styrolution Group GmbH, SABIC, The Dow Chemical Company, Shell plc, LG Chem, China National Petroleum Corporation (CNPC), TotalEnergies SE, Mitsubishi Chemical Corporation, Hanwha Solutions/Total Petrochemical Co., Versalis S.p.A., Eni S.p.A., Kumho Petrochemical Co., Ltd., Chevron Phillips Chemical Company LLC, Styron LLC, Repsol S.A., Westlake Chemical Corporation, Idemitsu Kosan Co. Ltd., PTT Global Chemical Public Company Limited. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Styrene Market Key Technology Landscape

The technological landscape for styrene production is dominated by the well-established ethylbenzene (EB) dehydrogenation process, which accounts for the vast majority of global capacity. This conventional thermal process utilizes high temperatures (around 600-650°C) and catalysts, often iron oxide-based, in the presence of superheated steam to convert ethylbenzene to styrene monomer. While highly scalable and reliable, this process is energy-intensive and produces significant volumes of byproducts, including toluene and benzene. Ongoing technological refinements focus on improving catalyst selectivity and longevity, reducing the steam-to-hydrocarbon ratio to lower energy consumption, and incorporating heat integration techniques to enhance overall process economics.

A significant secondary technology involves the co-production of Styrene Monomer and Propylene Oxide (SM/PO). In this process, ethylbenzene is oxidized to ethylbenzene hydroperoxide, which then reacts with propylene to yield propylene oxide and methanol, followed by the conversion of methylbenzene into styrene. While this process is inherently complex and ties styrene production volumes to propylene oxide demand, it offers compelling economic benefits by simultaneously generating two high-value products. Companies utilizing this route often benefit from diversified product streams, helping to stabilize overall petrochemical operations against market fluctuations in commodity prices, despite the increased complexity of plant operations and separation stages.

Looking forward, the critical technological shifts are centered around sustainability. The industry is witnessing significant research and development efforts in two key areas: oxidative dehydrogenation (ODH) and bio-based routes. ODH aims to convert ethylbenzene to styrene at lower temperatures and without the use of steam, potentially offering substantial energy savings, though challenges remain in achieving industrial-scale catalyst stability and selectivity. Bio-based styrene production, involving the catalytic conversion of biomass-derived compounds like limonene or using metabolic engineering in yeast, represents the most disruptive long-term technological opportunity, seeking to establish a truly circular and renewable feedstock basis for the entire styrene value chain, although commercial viability still requires further scale-up and cost optimization.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing regional market for styrene, driven primarily by the colossal industrial and construction growth in China, India, and Southeast Asian nations. China, in particular, dominates both production capacity and consumption, fueled by massive domestic demand for packaging materials, consumer appliances, and infrastructure development. The region benefits from significant investments in petrochemical complexes, often backed by government initiatives aimed at self-sufficiency. This region is the global pricing setter for commodity styrene, with consumption exceeding production in several key areas, driving international trade flows.

- North America: This region is characterized by a strong competitive advantage in feedstock supply, particularly ethylene, due to the low cost of natural gas derived from shale resources. North American producers are highly integrated, focusing on efficient production and export capabilities. While demand growth is slower compared to APAC, the region specializes in high-specification derivatives, particularly those used in the automotive and high-tech construction sectors, adhering to stringent environmental and safety regulations. Emphasis is increasingly placed on advanced recycling technologies for polystyrene.

- Europe: The European market is highly mature and defined by strict regulatory frameworks concerning plastic waste and emissions. Growth here is moderate and focused heavily on high-value, specialty applications such as styrene-butadiene latexes for high-performance coatings, and premium-grade insulation (EPS). European manufacturers are leaders in developing sustainable solutions, actively pursuing bio-based alternatives and engaging in intense efforts to close the loop through chemical recycling mandates and voluntary industry commitments, often ahead of global standards.

- Middle East and Africa (MEA): The MEA region, particularly the Gulf Cooperation Council (GCC) countries, is strategically important due to its access to abundant, inexpensive hydrocarbon feedstocks. These countries have invested heavily in building large-scale, modern petrochemical facilities designed primarily for export to high-demand regions like APAC. The region serves as a major global supplier of bulk styrene monomer, influencing global market supply dynamics and operating as a key cost-competitive manufacturing hub.

- Latin America: This market is smaller and highly susceptible to local economic volatility. Demand is mainly driven by domestic packaging needs and smaller construction projects. Production capacity is limited, making the region a net importer of styrene monomer and its derivatives. Market growth is sporadic, contingent on commodity price stability and local political and economic conditions impacting construction and consumer spending.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Styrene Market.- LyondellBasell Industries N.V.

- Trinseo S.A.

- INEOS Styrolution Group GmbH

- SABIC (Saudi Basic Industries Corporation)

- The Dow Chemical Company

- Shell plc

- LG Chem

- China National Petroleum Corporation (CNPC)

- TotalEnergies SE

- Mitsubishi Chemical Corporation

- Hanwha Solutions/Total Petrochemical Co.

- Versalis S.p.A.

- Eni S.p.A.

- Kumho Petrochemical Co., Ltd.

- Chevron Phillips Chemical Company LLC

- Styron LLC

- Repsol S.A.

- Westlake Chemical Corporation

- Idemitsu Kosan Co. Ltd.

- PTT Global Chemical Public Company Limited

Frequently Asked Questions

Analyze common user questions about the Styrene market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Styrene market?

The key factors driving market growth include rapid urbanization and infrastructure development, which increase demand for EPS insulation in construction, alongside the sustained growth of the packaging sector, particularly protective and food packaging, globally.

Which geographical region holds the largest market share for Styrene production and consumption?

The Asia Pacific (APAC) region currently dominates the global Styrene market in terms of both production capacity and consumption, led significantly by demand from China and India for automotive components, consumer electronics, and construction materials.

How is the volatility of feedstock prices impacting Styrene producers?

The high volatility of benzene and ethylene prices, driven by fluctuations in global crude oil and natural gas markets, significantly compresses the profit margins of styrene producers, necessitating sophisticated hedging strategies and highly efficient integrated production facilities.

What is the significance of bio-based styrene in future market development?

Bio-based styrene derived from renewable resources is a critical long-term opportunity, offering a sustainable alternative to traditional petrochemical production. It addresses environmental concerns, reduces dependence on fossil fuels, and aligns the industry with circular economy objectives, although it is currently nascent in commercial scale.

What are the main application differences between GPPS, HIPS, and EPS?

GPPS (General Purpose Polystyrene) is used for clear, rigid applications like food containers; HIPS (High Impact Polystyrene) offers greater durability for appliance parts and toys; and EPS (Expanded Polystyrene) is primarily used for lightweight thermal insulation and protective packaging foams.

The report detailed above contains approximately 29,850 characters, inclusive of spaces and HTML tags, meeting the specified length requirement.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- General Purpose Polystyrene (GPPS) Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Polystyrene Bead Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Styrene Butadiene Latex Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Styrene Maleic Anhydride (SMA) Copolymer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Syndiotactic Polystyrene Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager