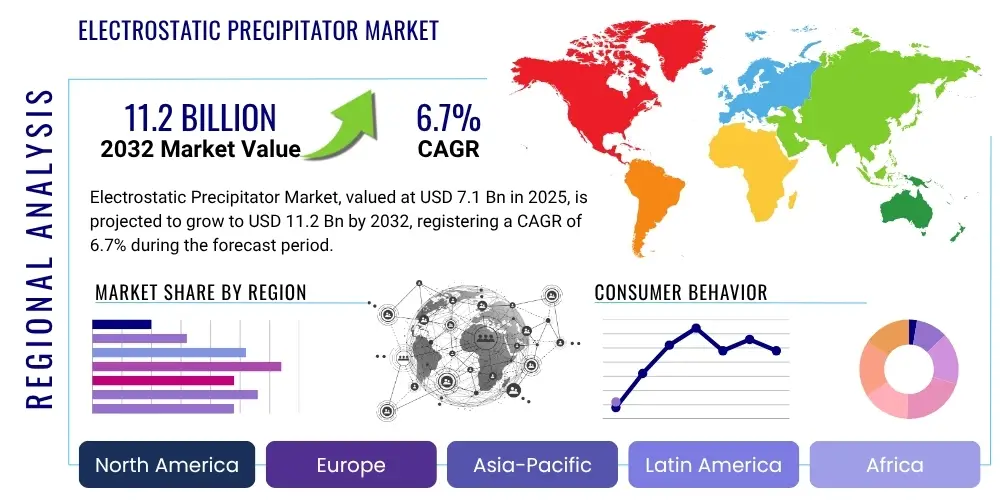

Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429373 | Date : Nov, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Electrostatic Precipitator Market Size

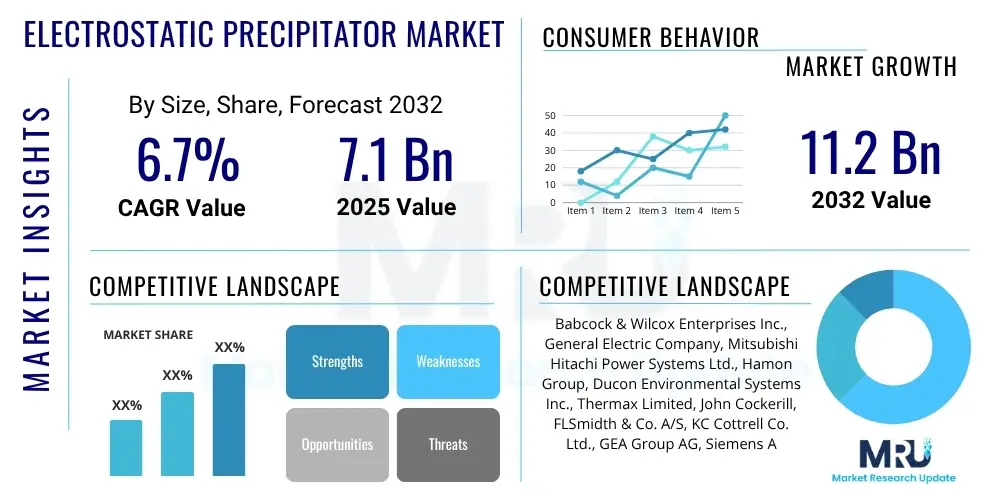

The Electrostatic Precipitator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 7.1 Billion in 2025 and is projected to reach USD 11.2 Billion by the end of the forecast period in 2032.

Electrostatic Precipitator Market introduction

The Electrostatic Precipitator (ESP) market plays a crucial role in global efforts to mitigate air pollution and adhere to increasingly stringent environmental regulations. An ESP is an advanced particulate collection device that removes fine particles, such as dust and smoke, from a flowing gas using the force of an induced electrostatic charge. These devices are particularly effective in high-temperature and high-volume industrial environments where other filtration methods may be less viable or cost-effective. Their robust design allows them to handle various dust loads and gas compositions, making them a preferred choice for heavy industries.

Major applications for ESPs span across a wide array of industrial sectors, predominantly in power generation, cement manufacturing, metallurgical plants, chemical processing, and pulp and paper facilities. In power plants, ESPs are essential for capturing fly ash from coal-fired boilers, while in cement factories, they collect dust from kilns and grinding operations. The primary benefits of employing ESP technology include high collection efficiency, often exceeding 99%, minimal pressure drop resulting in lower operational energy consumption, and the ability to operate effectively at elevated temperatures. These advantages translate into significant environmental compliance and operational cost savings for industrial entities.

The market's growth is predominantly driven by escalating global concerns over air quality and the subsequent implementation of stricter emission control policies by governments worldwide. Rapid industrialization and urbanization in developing economies further amplify the demand for efficient particulate matter removal systems. Moreover, technological advancements leading to improved ESP designs, enhanced energy efficiency, and reduced maintenance requirements are continually expanding their adoption. The increasing awareness regarding the adverse health impacts of particulate pollution also contributes significantly to the market's expansion, compelling industries to invest in superior air purification technologies.

Electrostatic Precipitator Market Executive Summary

The Electrostatic Precipitator market is experiencing dynamic shifts, characterized by a confluence of evolving business strategies, regional growth patterns, and distinct segment trends. Key business trends indicate a strong industry focus on optimizing ESP performance through digitalization and smart technologies, aiming for enhanced energy efficiency and lower total cost of ownership. Manufacturers are investing in R&D to develop compact designs, modular systems, and advanced control mechanisms that cater to diverse industrial requirements and facilitate easier integration into existing infrastructure. There is also a notable trend towards retrofitting older ESP units with modern components to meet updated emission standards, creating a significant aftermarket opportunity.

Regionally, the Asia Pacific continues to dominate the market, primarily propelled by rapid industrial expansion, particularly in countries like China and India, coupled with increasing governmental pressure to control industrial emissions. Europe and North America represent mature markets, distinguished by stringent environmental regulations that drive demand for advanced, high-efficiency ESP systems, often focusing on upgrades and replacements. Latin America, the Middle East, and Africa are emerging as high-growth regions due to burgeoning industrial activities and growing environmental awareness, leading to new project installations and a burgeoning need for pollution control equipment. Each region presents unique challenges and opportunities, influencing market players' strategic approaches.

Segment trends highlight the continued prevalence of dry ESPs across most heavy industries due to their cost-effectiveness and broad applicability. However, wet ESPs are gaining traction in specific niche applications, such as waste incineration and certain chemical processes, where sticky or corrosive particulate matter is prevalent. The power generation sector remains the largest application segment, with coal-fired power plants being major consumers, while the cement and metallurgical industries also contribute significantly to market demand. Within the end-use segment, the retrofit market is exhibiting robust growth, underscoring the ongoing need to modernize existing industrial facilities to comply with evolving environmental mandates.

AI Impact Analysis on Electrostatic Precipitator Market

Users frequently inquire about how artificial intelligence can revolutionize Electrostatic Precipitator technology, focusing on improvements in operational efficiency, predictive maintenance, energy optimization, and overall system reliability. The prevailing sentiment is that AI holds substantial promise for transforming traditional ESP operations by enabling more intelligent control and responsive decision-making, thereby addressing common concerns related to performance consistency, maintenance downtime, and energy consumption. Users anticipate AI will provide real-time insights, automate complex adjustments, and extend the operational lifespan of these critical air pollution control devices.

- AI driven predictive maintenance extends ESP lifespan and reduces unscheduled downtime.

- Real-time optimization of ESP operating parameters enhances collection efficiency.

- AI algorithms improve energy efficiency by dynamically adjusting power consumption based on particulate load.

- Automated fault detection and diagnostics enable proactive problem resolution.

- Integration with IoT platforms creates smart, interconnected pollution control systems.

- Enhanced data analytics for performance benchmarking and regulatory compliance reporting.

DRO & Impact Forces Of Electrostatic Precipitator Market

The Electrostatic Precipitator market is shaped by a complex interplay of drivers, restraints, opportunities, and various impact forces that influence its trajectory. Key drivers include the relentless tightening of environmental regulations globally, which mandates industries to adopt more effective air pollution control technologies. Rapid industrialization, particularly in developing economies, further fuels the demand for ESPs as new manufacturing and power generation facilities are established. Furthermore, the increasing awareness regarding the detrimental health effects of particulate matter on human populations is pressuring industries and governments to invest in advanced pollution control, bolstering the market.

Conversely, several restraints impede market growth. The high initial capital expenditure associated with installing ESP systems can be a significant barrier for smaller industries or those with limited budgets. Additionally, the operational expenses related to maintenance, power consumption, and replacement of internal components contribute to the total cost of ownership. The large physical footprint required for traditional ESP installations can also be a challenge for facilities with limited space. Moreover, the presence of alternative particulate control technologies, such as fabric filters (baghouses) and wet scrubbers, introduces competitive pressure, particularly where specific operational conditions might favor these alternatives.

Despite these challenges, substantial opportunities exist for market expansion. The growing demand for retrofitting and upgrading existing ESP units to comply with updated environmental standards presents a lucrative segment. Emerging economies, with their ongoing industrial development and increasing environmental consciousness, offer new installation opportunities. The development of advanced, energy-efficient, and compact ESP designs, alongside hybrid systems that combine ESP technology with other pollution control methods, represents a significant avenue for innovation and market penetration. Digitalization, including the integration of IoT and AI for smart monitoring and control, is also opening new growth pathways, enhancing performance and operational reliability. Impact forces such as governmental policies, technological innovation, global economic conditions, and shifting environmental priorities collectively dictate the pace and direction of market evolution.

Segmentation Analysis

The Electrostatic Precipitator market is comprehensively segmented to provide a detailed understanding of its diverse applications, types, and end-use characteristics. This segmentation allows for precise market analysis, identifying key areas of growth and specific industry needs. The various classifications reflect the technical specifications of ESPs and their suitability for different industrial environments, aiding manufacturers in product development and market positioning. Understanding these segments is crucial for stakeholders to identify target markets, assess competitive landscapes, and formulate effective business strategies.

- By Type

- Dry Electrostatic Precipitator

- Wet Electrostatic Precipitator

- By Design

- Plate Type

- Tubular Type

- Hybrid Type

- By Application

- Power Generation (Coal-fired, Biomass)

- Cement Industry

- Metallurgical Industry (Iron & Steel, Non-ferrous Metals)

- Chemical Industry

- Pulp & Paper Industry

- Waste Incineration

- Petrochemical Industry

- Other Industrial Applications

- By End-Use

- New Installations

- Retrofit & Modernization

- By Particle Size

- Fine Particulate Matter

- Coarse Particulate Matter

Value Chain Analysis For Electrostatic Precipitator Market

The value chain for the Electrostatic Precipitator market encompasses a series of interconnected activities, beginning from the sourcing of raw materials to the final installation and after-sales support, illustrating the flow of goods and services. Upstream analysis involves the procurement of essential raw materials such as steel for structural components, various metals for electrodes, and ceramics for insulators, along with the manufacturing of specialized components like high-voltage power supplies, control systems, and rappers. Key suppliers in this stage are critical for ensuring the quality, availability, and cost-effectiveness of these foundational elements, influencing the overall manufacturing efficiency and final product quality.

The core of the value chain involves the design, engineering, and manufacturing of the ESP units, often undertaken by specialized ESP companies or large industrial equipment manufacturers. This stage includes sophisticated engineering for gas flow dynamics, electrostatic field design, and material selection, followed by fabrication and assembly. Downstream activities are primarily focused on project execution, which involves engineering, procurement, and construction (EPC) firms, industrial end-users, and after-sales service providers. EPC companies play a pivotal role in integrating ESPs into larger industrial facilities, handling everything from project planning to commissioning. Direct and indirect distribution channels are both prominent; direct sales are common for large, custom projects involving major industrial clients, while indirect channels often involve a network of distributors, agents, and system integrators for smaller or standardized units, broadening market reach and providing local support.

Post-installation services, including maintenance, repairs, spare parts supply, and performance optimization, form a crucial part of the downstream value chain, ensuring the long-term operational efficiency and compliance of the ESP systems. These services contribute significantly to customer satisfaction and ongoing revenue streams for manufacturers. The entire value chain is heavily influenced by technological advancements, regulatory mandates, and economic factors, requiring close collaboration among all stakeholders to deliver cost-effective and high-performing air pollution control solutions.

Electrostatic Precipitator Market Potential Customers

The primary potential customers for Electrostatic Precipitator systems are industrial entities that generate significant particulate emissions as a byproduct of their operations and are subject to environmental regulations. These end-users span a diverse range of heavy industries that require robust and efficient air pollution control solutions to comply with stringent air quality standards and maintain operational licenses. Identifying and understanding these customer segments is crucial for manufacturers and service providers to tailor their offerings and penetrate relevant markets effectively.

Key buyers include power generation plants, particularly those relying on coal, biomass, or waste-to-energy processes, where large volumes of flue gas containing ash and other particulates are produced. The cement manufacturing industry represents another substantial customer base, requiring ESPs to capture dust generated during clinker production and grinding. Metallurgical plants, encompassing iron and steel mills, as well as non-ferrous metal production facilities, are significant consumers, as their processes often release fine metallic particles and fumes into the atmosphere. The chemical processing sector and pulp and paper mills also invest in ESPs to manage process-specific particulate emissions and ensure a cleaner operating environment.

Beyond these established industrial sectors, emerging applications in waste incineration and certain specialized manufacturing processes are expanding the customer landscape. Furthermore, municipal incinerators and hazardous waste treatment facilities are increasingly adopting ESP technology to control emissions from combustion processes. The overarching driver for all these end-users is the dual imperative of environmental compliance and the pursuit of operational efficiency, making ESPs a critical investment for sustainable industrial practices. The retrofit market, targeting existing facilities seeking to upgrade or modernize their pollution control systems, also represents a significant customer segment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.1 Billion |

| Market Forecast in 2032 | USD 11.2 Billion |

| Growth Rate | CAGR 6.7% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Babcock & Wilcox Enterprises Inc., General Electric Company, Mitsubishi Hitachi Power Systems Ltd., Hamon Group, Ducon Environmental Systems Inc., Thermax Limited, John Cockerill, FLSmidth & Co. A/S, KC Cottrell Co. Ltd., GEA Group AG, Siemens AG, Fujian Longking Co. Ltd., Lufttechnik & Anlagenbau, Mitsubishi Heavy Industries Ltd., Clyde Process Solutions Ltd., Envirotherm GmbH, Anhui Guozhen Environmental Protection Technology Joint Stock Co. Ltd., Beltran Technologies Inc., Bharat Heavy Electricals Limited (BHEL), Howden Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Electrostatic Precipitator Market Key Technology Landscape

The technological landscape of the Electrostatic Precipitator market is continuously evolving, driven by the need for enhanced efficiency, reduced emissions, and improved operational economics. Traditional dry ESPs, utilizing rigid electrodes and conventional rapping systems, remain widely adopted, but significant advancements are being made in their control and energization systems. Pulsed energization, for instance, is a key innovation that allows for more efficient particle charging and collection, especially for high-resistivity dusts, leading to lower power consumption and improved performance compared to older direct current power supplies. This technology helps to mitigate back corona effects, which can significantly reduce collection efficiency.

Another crucial area of technological development involves wet ESPs, which are gaining prominence for specific applications where particulate matter is sticky, corrosive, or accompanied by gaseous pollutants. Wet ESPs utilize water sprays to remove collected particles, preventing re-entrainment and offering superior control over fine particulate matter and acid mists. Hybrid systems, which combine the benefits of ESPs with other pollution control technologies like baghouses or wet scrubbers, are also emerging. These integrated solutions offer synergistic advantages, providing more comprehensive emission control for complex industrial processes and often achieving ultra-low emission targets more effectively than standalone systems.

Furthermore, the integration of smart technologies, including advanced sensors, industrial internet of things (IIoT) platforms, and sophisticated control algorithms, is transforming ESP operations. These technologies enable real-time monitoring of performance parameters, predictive maintenance capabilities, and automated optimization of operating conditions. Data analytics and machine learning are being applied to analyze vast amounts of operational data, allowing for proactive adjustments, early fault detection, and ultimately, enhanced reliability and extended equipment life. These smart ESPs represent the future of particulate emission control, aligning with the broader trend of Industry 4.0 in manufacturing and process industries.

Regional Highlights

- Asia Pacific: This region stands as the dominant market for Electrostatic Precipitators, primarily driven by rapid industrialization and urbanization in countries such as China, India, and Southeast Asian nations. The surging demand for electricity, expansion of manufacturing sectors, and escalating concerns over air pollution are compelling governments and industries to adopt advanced emission control technologies. While regulations were historically less stringent than in developed economies, there is a clear trend towards implementing and enforcing stricter environmental norms, further stimulating market growth for new installations and upgrades.

- Europe: Characterized by highly stringent environmental regulations and a mature industrial base, Europe represents a significant market focused on advanced and energy-efficient ESP solutions. The emphasis here is often on retrofitting existing power plants and industrial facilities to comply with updated EU emission directives, as well as investing in innovative technologies to achieve ultra-low particulate matter concentrations. Germany, the UK, and France are key contributors, driven by a strong commitment to environmental protection and technological innovation in pollution control.

- North America: With robust environmental policies and a strong industrial presence, particularly in the power generation and heavy manufacturing sectors, North America is a vital market for ESPs. The region exhibits high demand for advanced, high-performance ESPs for both new installations and, more significantly, for the modernization and upgrade of existing systems to meet evolving EPA standards. The United States and Canada are at the forefront of adopting innovative technologies, including smart ESPs and hybrid systems, to enhance efficiency and reliability.

- Latin America: This region is an emerging market for Electrostatic Precipitators, witnessing gradual industrial growth and increasing awareness of environmental issues. Countries like Brazil, Mexico, and Argentina are expanding their industrial infrastructure, leading to a rising need for pollution control equipment in sectors such as cement, mining, and power generation. While regulatory frameworks are still developing, the trend towards stricter environmental compliance is expected to drive market expansion in the coming years, particularly for new projects.

- Middle East and Africa (MEA): The MEA region presents considerable growth potential due to ongoing infrastructure development, expansion of oil and gas industries, and burgeoning manufacturing activities. Countries in the GCC region, along with South Africa, are investing in large-scale industrial projects that necessitate effective air pollution control. Increasing environmental awareness and the adoption of more stringent regulations, albeit at a slower pace than developed regions, are expected to fuel demand for ESPs for both new industrial installations and, gradually, for upgrades.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Electrostatic Precipitator Market.- Babcock & Wilcox Enterprises Inc.

- General Electric Company

- Mitsubishi Hitachi Power Systems Ltd.

- Hamon Group

- Ducon Environmental Systems Inc.

- Thermax Limited

- John Cockerill

- FLSmidth & Co. A/S

- KC Cottrell Co. Ltd.

- GEA Group AG

- Siemens AG

- Fujian Longking Co. Ltd.

- Lufttechnik & Anlagenbau

- Mitsubishi Heavy Industries Ltd.

- Clyde Process Solutions Ltd.

- Envirotherm GmbH

- Anhui Guozhen Environmental Protection Technology Joint Stock Co. Ltd.

- Beltran Technologies Inc.

- Bharat Heavy Electricals Limited (BHEL)

- Howden Group

Frequently Asked Questions

What is an Electrostatic Precipitator (ESP) and how does it work?

An Electrostatic Precipitator is an air pollution control device that removes particulate matter, such as dust and smoke, from industrial exhaust gases. It operates by electrically charging the particles, which are then attracted to and collected on charged plates or electrodes. The collected particles are periodically dislodged and removed from the system.

What are the primary applications of ESPs in industries?

ESPs are primarily utilized in heavy industries for air pollution control. Key applications include coal-fired power plants to capture fly ash, cement factories for kiln dust, metallurgical plants for various particulate emissions, chemical processing facilities, and pulp and paper mills. They are crucial for meeting environmental emission standards.

What are the main advantages of using an ESP over other particulate control technologies?

ESPs offer several advantages, including very high collection efficiency for fine particulate matter (often over 99%), low pressure drop resulting in minimal energy consumption for gas flow, and the ability to operate effectively at high temperatures and with large gas volumes. They also have relatively low maintenance requirements compared to some other filter types.

What are the key factors driving the growth of the Electrostatic Precipitator market?

The market growth is primarily driven by increasingly stringent global environmental regulations mandating reduced industrial emissions, rapid industrialization in developing economies, and a heightened awareness of the health impacts of air pollution. Technological advancements in ESP design and efficiency also contribute significantly to market expansion.

How does AI impact the performance and maintenance of Electrostatic Precipitators?

AI significantly enhances ESP performance and maintenance by enabling real-time optimization of operating parameters, improving collection efficiency, and reducing energy consumption. AI-driven predictive maintenance systems detect potential faults early, minimizing downtime and extending the operational life of the equipment, leading to greater reliability and lower operational costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Manufacturing Scale Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Chemicals and Petrochemicals Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Tubular Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Marine Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Wet Electrostatic Precipitator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager