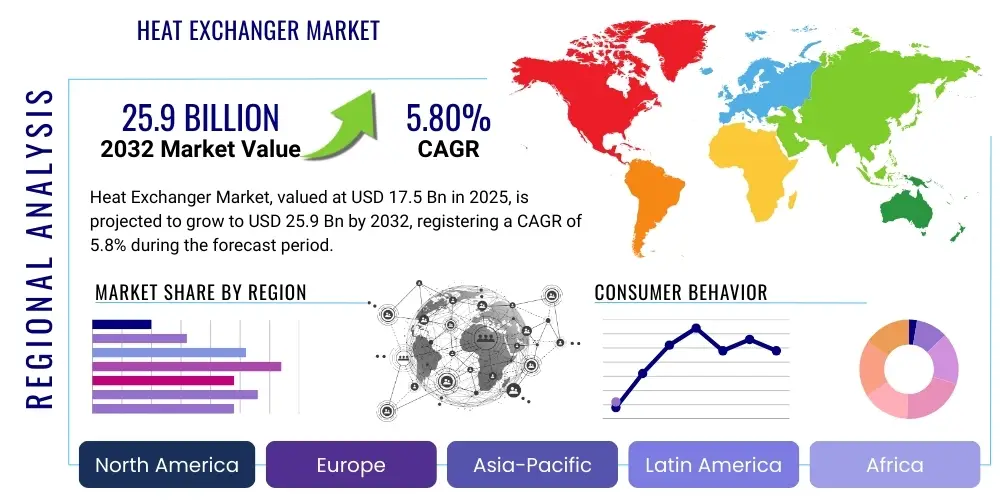

Heat Exchanger Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427378 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Heat Exchanger Market Size

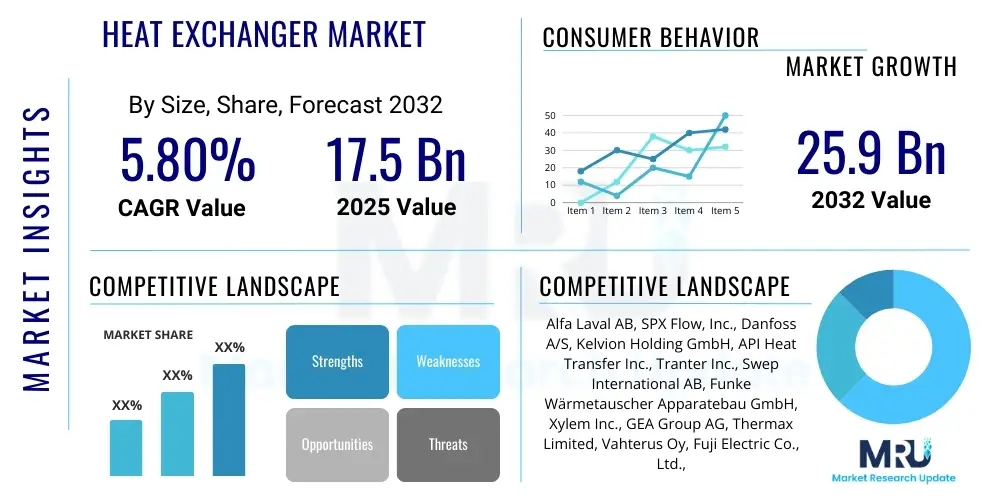

The Heat Exchanger Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 17.5 billion in 2025 and is projected to reach USD 25.9 billion by the end of the forecast period in 2032. This robust expansion is primarily driven by increasing demand for energy-efficient industrial processes, stringent environmental regulations promoting heat recovery, and significant investments in the chemical, petrochemical, oil and gas, and HVAC sectors globally. The markets growth trajectory is further supported by the continuous need for optimized thermal management solutions across diverse applications, from large-scale power generation to specialized automotive systems.

Heat Exchanger Market introduction

The global Heat Exchanger Market encompasses a wide array of devices designed to efficiently transfer thermal energy between two or more fluids, typically at different temperatures, without allowing them to mix. These critical components are fundamental to countless industrial and commercial processes, enabling everything from precise temperature control in manufacturing to energy recovery in power plants. Their operational principle relies on maximizing the surface area for heat exchange, often incorporating sophisticated designs to optimize thermal conductivity and flow dynamics, thereby minimizing energy consumption and enhancing overall system efficiency.

Heat exchangers are broadly categorized by their construction type, including shell and tube, plate and frame, air-cooled, finned tube, and spiral designs, each tailored for specific operational pressures, temperatures, and fluid characteristics. Major applications span across the oil and gas industry for refining and processing, chemical and petrochemical sectors for reaction control and product cooling, power generation for steam condensation and preheating, and the expansive HVAC&R (Heating, Ventilation, Air Conditioning, and Refrigeration) market for climate control. They are also indispensable in automotive systems for engine cooling, in food and beverage processing for pasteurization and sterilization, and in pharmaceuticals for precise temperature management during drug manufacturing.

The inherent benefits of utilizing heat exchangers are substantial, including significant energy savings through heat recovery, improved process efficiency, enhanced product quality due to stable temperature control, and reduced operational costs. The market is propelled by several key driving factors, notably the global push for industrial digitalization and automation, the escalating demand for sustainable energy solutions, and the increasing stringency of environmental regulations mandating reduced emissions and improved energy utilization. Furthermore, rapid industrialization in emerging economies and the modernization of existing infrastructure in developed regions continue to fuel the adoption of advanced heat exchanger technologies.

Heat Exchanger Market Executive Summary

The Heat Exchanger Market is undergoing significant transformation, characterized by robust business trends focusing on innovation, efficiency, and sustainability. Key business trends include the increasing demand for compact and modular designs, a growing emphasis on custom-engineered solutions tailored to specific industry needs, and the integration of advanced materials to withstand harsh operating conditions and enhance performance. Digitalization plays a pivotal role, with manufacturers incorporating IoT sensors for real-time monitoring and predictive maintenance, and leveraging AI and machine learning for optimized design and operational efficiency. The market is also seeing a shift towards more sustainable solutions, driven by circular economy principles and the imperative for lower carbon footprints across industries.

From a regional perspective, Asia Pacific remains the dominant and fastest-growing market, propelled by rapid industrialization, massive infrastructure development, and substantial investments in the chemical, power generation, and manufacturing sectors, particularly in countries like China, India, and Southeast Asian nations. North America and Europe demonstrate a strong demand for advanced and energy-efficient heat exchangers, driven by stringent environmental regulations, a focus on upgrading aging industrial infrastructure, and the adoption of renewable energy technologies. The Middle East and Africa exhibit significant growth potential due supported by expansion in oil and gas, petrochemicals, and water treatment projects, while Latin America is experiencing gradual growth fueled by industrial recovery and investments in mining and energy sectors.

Segmentation trends indicate a strong preference for plate and frame heat exchangers due to their high efficiency, compact design, and ease of maintenance, making them ideal for various applications in HVAC, food and beverage, and chemical processing. Shell and tube heat exchangers, despite their larger footprint, continue to hold a substantial share due to their robustness and suitability for high-pressure and high-temperature environments in heavy industries like oil and gas and power generation. The demand for air-cooled heat exchangers is also rising, especially in water-scarce regions or applications where water conservation is critical. Furthermore, there is an increasing adoption of specialized materials such as titanium and advanced alloys, driven by the need for corrosion resistance and enhanced performance in aggressive fluid environments.

AI Impact Analysis on Heat Exchanger Market

The integration of Artificial intelligence (AI) is poised to revolutionize the Heat Exchanger Market by addressing critical operational and design challenges, leading to enhanced efficiency, reduced costs, and improved predictive capabilities. Users are increasingly questioning how AI can move beyond simple data analysis to enable proactive maintenance strategies, optimize design parameters for specific applications, and minimize energy consumption. The core themes revolve around leveraging AI for more intelligent and adaptive systems that can predict failures, recommend optimal operating conditions, and even facilitate the design of next-generation heat exchangers with unparalleled performance. There is significant expectation for AI to transform the lifecycle management of these critical industrial components, from conception to end-of-life, ensuring maximum uptime and sustainable operation.

Common concerns and expectations highlight the desire for AI to not only improve existing processes but also to unlock new potentials in heat transfer technology. Users are keen to understand AIs role in creating self-optimizing heat exchanger networks, managing complex fluid dynamics, and adapting to fluctuating operational demands in real-time. The emphasis is on tangible benefits such as extending equipment lifespan, reducing unscheduled downtime through accurate fault prediction, and achieving significant energy savings by maintaining peak operational efficiency. The market anticipates AI as a key enabler for transitioning towards smart manufacturing and Industry 4.0 paradigms within the heat exchanger domain, fundamentally changing how these systems are designed, operated, and maintained to meet evolving industrial requirements and environmental standards.

- AI-driven Predictive Maintenance: Enables early detection of potential failures, reducing unscheduled downtime and maintenance costs.

- Optimized Design and Simulation: AI algorithms enhance the design process by rapidly exploring vast design spaces, optimizing for efficiency, size, and material use.

- Real-time Performance Optimization: AI systems monitor operational data to adjust parameters, ensuring heat exchangers run at peak efficiency.

- Energy Efficiency Enhancement: AI identifies opportunities for heat recovery and minimizes energy losses through intelligent control.

- Fault Diagnosis and Anomaly Detection: AI models can pinpoint abnormal operational patterns, preventing major breakdowns.

- Material Selection Guidance: AI assists in choosing optimal materials for specific applications, considering corrosion resistance and thermal properties.

- Automated Quality Control: AI-powered vision systems improve inspection accuracy during manufacturing.

- Enhanced Process Control: AI integrates with other industrial systems for holistic process optimization involving heat exchangers.

DRO & Impact Forces Of Heat Exchanger Market

The Heat Exchanger Market is significantly influenced by a confluence of drivers, restraints, and opportunities, collectively shaped by various impact forces. Key drivers include the escalating global demand for energy efficiency across industrial processes, stringent environmental regulations promoting waste heat recovery and reduced emissions, and substantial investments in infrastructure development, particularly in emerging economies. The continuous expansion of sectors such as oil and gas, petrochemicals, chemical processing, power generation, and HVAC&R further fuels the adoption of diverse heat exchanger technologies. Additionally, the increasing need for precise temperature control in sensitive applications like pharmaceuticals and food and beverage processing contributes to market growth.

Despite the robust driving forces, the market faces notable restraints. The high initial capital investment required for advanced heat exchanger systems can be a barrier for small and medium-sized enterprises. Fluctuations in raw material prices, particularly for metals like stainless steel, titanium, and nickel alloys, impact manufacturing costs and market stability. The complexity of maintenance, the need for specialized expertise, and the potential for fouling and corrosion further present operational challenges. Moreover, the long lifespan of existing heat exchanger installations can sometimes limit the rapid adoption of newer, more efficient technologies, creating a replacement cycle that is slower than desired.

Opportunities for growth are abundant, primarily in the development and adoption of compact, lightweight, and modular heat exchangers that offer enhanced performance in smaller footprints. The increasing focus on sustainable solutions, including those designed for renewable energy systems (e.g., geothermal, concentrated solar power) and waste-to-energy applications, presents a lucrative avenue. Customization and engineering of application-specific solutions, coupled with the integration of smart technologies such as IoT and AI for predictive maintenance and operational optimization, also offer significant market potential. The burgeoning industrialization and urbanization in developing regions provide a fertile ground for market expansion, alongside continuous innovation in materials science to develop more durable and efficient heat exchange surfaces. These market dynamics are critically shaped by technological advancements, evolving environmental policies, and global economic conditions.

Segmentation Analysis

The Heat Exchanger Market is extensively segmented to provide a detailed understanding of its diverse landscape and cater to various industrial and commercial requirements. This segmentation allows for targeted product development, strategic market positioning, and a clear view of demand patterns across different applications and technologies. Understanding these segments is crucial for stakeholders to identify growth areas, assess competitive landscapes, and formulate effective business strategies. The market is primarily bifurcated by product type, material, application, and end-use industry, reflecting the specialized needs and operational environments inherent in heat transfer processes.

Each segment offers unique characteristics and growth trajectories, driven by specific technological advancements, regulatory mandates, and industry-specific demands. For instance, the choice of heat exchanger type is dictated by factors such as operating pressure, temperature range, fluid characteristics, and space availability. Similarly, material selection is paramount, considering aspects like corrosion resistance, thermal conductivity, and cost-effectiveness for a given application. The broad range of applications, from heavy industrial processes to sensitive pharmaceutical manufacturing, necessitates a granular approach to market analysis, highlighting the versatility and critical role of heat exchangers in modern industry. This structured approach to segmentation provides clarity on market dynamics and facilitates informed decision-making for manufacturers, suppliers, and end-users.

- By Type:

- Shell and Tube Heat Exchangers

- Plate and Frame Heat Exchangers

- Air Cooled Heat Exchangers

- Finned Tube Heat Exchangers

- Gasketed Plate Heat Exchangers

- Brazed Plate Heat Exchangers

- Welded Plate Heat Exchangers

- Spiral Heat Exchangers

- Others (e.g., Double Pipe, Scraped Surface)

- By Material:

- Stainless Steel

- Carbon Steel

- Titanium

- Nickel and Nickel Alloys

- Copper and Copper Alloys

- Aluminum

- Graphite

- Others (e.g., Special Alloys, Non-metallic materials)

- By Application:

- Heating

- Cooling

- Condensing

- Evaporating

- Heat Recovery

- Pasteurization

- Sterilization

- By End-Use Industry:

- Oil and Gas

- Chemical and Petrochemical

- Power Generation (Thermal, Nuclear, Renewable)

- HVAC and Refrigeration

- Food and Beverage

- Automotive

- Marine

- Pharmaceutical

- Metallurgy

- Paper and Pulp

- Others (e.g., Data Centers, Textile)

Heat Exchanger Market Value Chain Analysis

The Heat Exchanger Markets value chain is a complex ecosystem spanning raw material sourcing to end-user services, encompassing multiple stages that add value to the final product. Upstream activities involve the procurement of critical raw materials, primarily various grades of metals such as stainless steel, carbon steel, titanium, and nickel alloys, along with gaskets, brazing materials, and specialized coatings. Key players at this stage include metal foundries, material suppliers, and component manufacturers who provide tubes, plates, fins, and other essential parts. Additionally, design software providers and engineering consultancies contribute significantly to the initial conceptualization and optimization phases, influencing the efficiency and cost-effectiveness of the final heat exchanger unit.

Midstream activities are dominated by the manufacturing and assembly of heat exchangers. This involves sophisticated processes like welding, brazing, pressing, and machining to construct the various types of heat exchangers, from shell and tube to plate and frame. Manufacturers often specialize in certain types or applications, leveraging advanced production techniques and quality control measures. These manufacturers also engage in research and development to innovate new designs, enhance heat transfer efficiency, and incorporate advanced materials. The focus at this stage is on engineering excellence, manufacturing precision, and adherence to industry standards and certifications.

Downstream activities encompass the distribution, installation, commissioning, and after-sales services for heat exchangers. The distribution channel involves a mix of direct sales by manufacturers to large industrial clients, and indirect sales through a network of distributors, agents, and system integrators who cater to a broader range of customers and specialized applications. Installation services, often provided by third-party contractors or specialized teams, are crucial for ensuring optimal performance. Post-sale, maintenance, repair, spare parts supply, and retrofitting services form a vital part of the value chain, ensuring the longevity and continued efficiency of the heat exchangers. The close collaboration between manufacturers, distributors, and service providers is essential for delivering comprehensive solutions and maintaining customer satisfaction throughout the product lifecycle.

Heat Exchanger Market Potential Customers

The Heat Exchanger Market serves an extraordinarily diverse range of potential customers, primarily end-users and buyers whose industrial or commercial processes necessitate efficient thermal management. These customers represent a broad spectrum of industries, each with specific requirements for heat transfer, temperature control, and energy recovery. Key sectors include the energy industry, encompassing oil and gas exploration, refining, and petrochemical processing, where heat exchangers are vital for various stages of production, separation, and transformation of hydrocarbons. In power generation, utilities ranging from conventional thermal power plants to nuclear and emerging renewable energy facilities (e.g., geothermal, concentrated solar power) rely heavily on heat exchangers for steam generation, condensation, and cooling processes to maximize efficiency and output.

Another significant customer segment is the manufacturing sector, particularly the chemical and process industries, which utilize heat exchangers for reaction cooling, solvent recovery, and temperature stabilization of products. The HVAC&R industry forms a massive customer base, integrating heat exchangers into air conditioning systems, refrigeration units, and heating applications for commercial buildings, residential complexes, and industrial facilities. The food and beverage industry also represents a critical market, requiring sanitary and precise heat exchangers for pasteurization, sterilization, cooking, and cooling processes to ensure product quality and safety. Similarly, the pharmaceutical and biotechnology sectors depend on highly specialized, often sterile, heat exchangers for drug manufacturing, fermentation, and purification processes where precise temperature control is paramount.

Beyond these major industries, potential customers extend to the automotive sector for engine cooling and climate control, marine applications for ship engine cooling and onboard HVAC, and metallurgy for cooling furnaces and industrial equipment. Furthermore, emerging applications in data centers for efficient server cooling, waste-to-energy plants for heat recovery, and water treatment facilities for desalination and wastewater processing are expanding the customer base. The broad applicability of heat exchangers across such varied end-use industries underscores their indispensable role in modern industrial society, making efficiency, reliability, and customization key considerations for potential buyers. Manufacturers continuously adapt their product offerings to meet the specific demands, regulatory compliance, and performance expectations of this diverse customer landscape.

Heat Exchanger Market Key Technology Landscape

The Heat Exchanger Market is characterized by a dynamic and evolving technology landscape focused on enhancing efficiency, reducing environmental impact, and improving operational reliability. A significant area of innovation involves advanced materials, with research and development efforts concentrating on high-performance alloys such as titanium, nickel alloys, and specialized stainless steels that offer superior corrosion resistance, high-temperature strength, and improved thermal conductivity. These materials are crucial for extending equipment lifespan in aggressive environments and for enabling more compact and lightweight designs. Non-metallic materials like graphite and ceramics are also gaining traction for specific applications requiring extreme chemical resistance or very high temperatures, expanding the range of operational possibilities.

Furthermore, advancements in manufacturing techniques are revolutionizing the design and production of heat exchangers. Additive manufacturing, or 3D printing, is emerging as a game-changer, allowing for the creation of complex internal geometries and intricate heat transfer surfaces that were previously impossible with traditional methods. This technology enables custom-designed heat exchangers with optimized flow paths and significantly enhanced heat transfer coefficients, leading to smaller footprints and higher performance. Modular designs are another key trend, offering flexibility, scalability, and ease of maintenance, allowing for quick installation and replacement of components, thereby reducing downtime and operational costs. These modular units can be readily adapted to various process requirements, providing a versatile solution for diverse industrial needs.

Digitalization and smart technologies are increasingly integrated into heat exchanger systems, forming a critical part of the technology landscape. The incorporation of Internet of Things (IoT) sensors enables real-time monitoring of operational parameters such as temperature, pressure, and flow rates, providing invaluable data for performance analysis. This data, when combined with Artificial Intelligence (AI) and Machine Learning (ML) algorithms, facilitates predictive maintenance, allowing for the early detection of potential failures and proactive scheduling of repairs, thereby minimizing unscheduled downtime. AI and ML are also being leveraged for design optimization, simulating various configurations to achieve maximum efficiency and minimal material usage. Additionally, enhanced heat transfer surfaces, such as microchannel designs, corrugated plates, and extended surfaces (fins), are continuously being refined to maximize the heat transfer area and improve overall thermal performance within a reduced volume, contributing significantly to energy savings and operational efficiency across numerous applications.

Regional Highlights

- Asia Pacific: This region dominates the global heat exchanger market, driven by rapid industrialization, significant investments in power generation (thermal and renewable), chemical and petrochemical industries, and robust growth in HVAC and refrigeration sectors in countries like China, India, and Southeast Asian nations. The regions expanding manufacturing base and increasing energy demands are key accelerators.

- North America: Characterized by a strong focus on upgrading aging infrastructure, adopting energy-efficient technologies, and stringent environmental regulations. Demand is robust in the oil and gas (especially refining), chemical, HVAC, and power generation sectors. Innovation in compact and high-performance heat exchangers is a key trend.

- Europe: The European market is highly mature and innovation-driven, with a strong emphasis on sustainability, decarbonization, and renewable energy integration. Strict environmental policies and the push for energy efficiency in industries like chemical, food and beverage, and HVAC are major drivers. There is a significant market for specialized and customized heat exchange solutions.

- Middle East and Africa: This region exhibits high growth potential, primarily due to ongoing investments in the oil and gas industry, petrochemical expansions, infrastructure development, and significant projects in water treatment and desalination. The demand for robust and corrosion-resistant heat exchangers suitable for harsh operating conditions is particularly high.

- Latin America: Experiencing steady growth, influenced by economic recovery, industrial development, and investments in mining, energy, and food processing sectors. Countries like Brazil and Mexico are leading the demand for heat exchangers, particularly in petrochemical and HVAC applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heat Exchanger Market.- Alfa Laval AB

- SPX Flow, Inc.

- Danfoss A/S

- Kelvion Holding GmbH

- API Heat Transfer Inc.

- Tranter Inc.

- Swep International AB (Daikin Group)

- Funke Wärmetauscher Apparatebau GmbH

- Xylem Inc.

- GEA Group AG

- Thermax Limited

- Vahterus Oy

- Fuji Electric Co., Ltd.

- Hitachi, Ltd.

- WCR Inc.

Frequently Asked Questions

What is a heat exchanger and how does it work?

A heat exchanger is a device that transfers heat between two or more fluids at different temperatures without allowing them to mix. It works by bringing the fluids into thermal contact, often separated by a conductive surface, to enable efficient heat transfer from the hotter fluid to the cooler one, driven by the temperature difference.

What are the main types of heat exchangers?

The main types include shell and tube, plate and frame (gasketed, brazed, welded), air-cooled, finned tube, and spiral heat exchangers. Each type is designed for specific applications based on factors like fluid properties, pressure, temperature, and space constraints.

Which industries heavily rely on heat exchangers?

Key industries that heavily rely on heat exchangers include oil and gas, chemical and petrochemical, power generation, HVAC and refrigeration, food and beverage, automotive, and pharmaceuticals. They are critical for processes like cooling, heating, condensation, and heat recovery across these sectors.

How do heat exchangers contribute to energy efficiency?

Heat exchangers significantly contribute to energy efficiency by facilitating the recovery of waste heat from industrial processes, which can then be reused to preheat incoming fluids or generate power. This reduces the need for external energy sources, lowering operational costs and greenhouse gas emissions.

What are the latest technological advancements in the heat exchanger market?

Recent advancements include the use of advanced materials for enhanced corrosion resistance and thermal performance, additive manufacturing for complex and optimized geometries, modular designs for flexibility, and the integration of IoT and AI for real-time monitoring, predictive maintenance, and operational optimization.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Plate Finned Heat Exchanger Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Multitube Heat Exchanger Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Impervious Graphite Heat Exchanger Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Automotive Heat Exchanger Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Plate Heat Exchanger Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager