Fiber Laser Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430354 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Fiber Laser Market Size

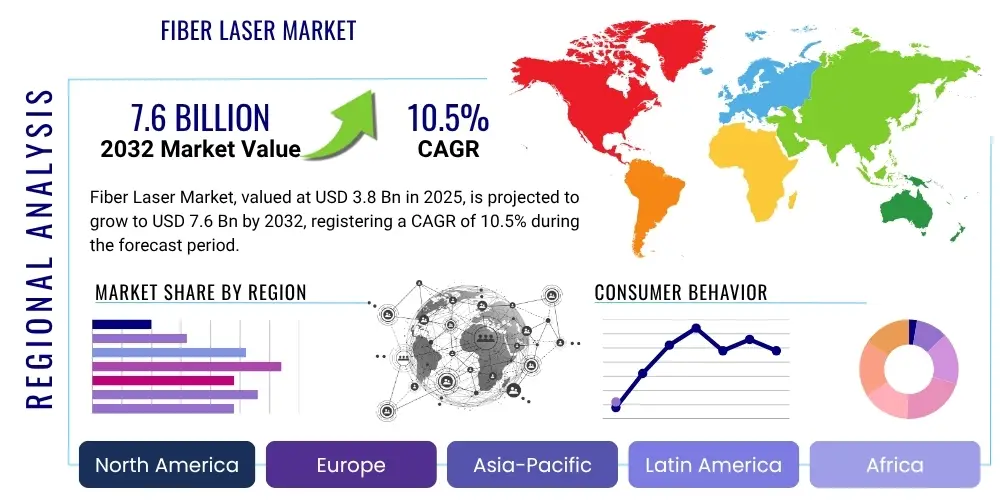

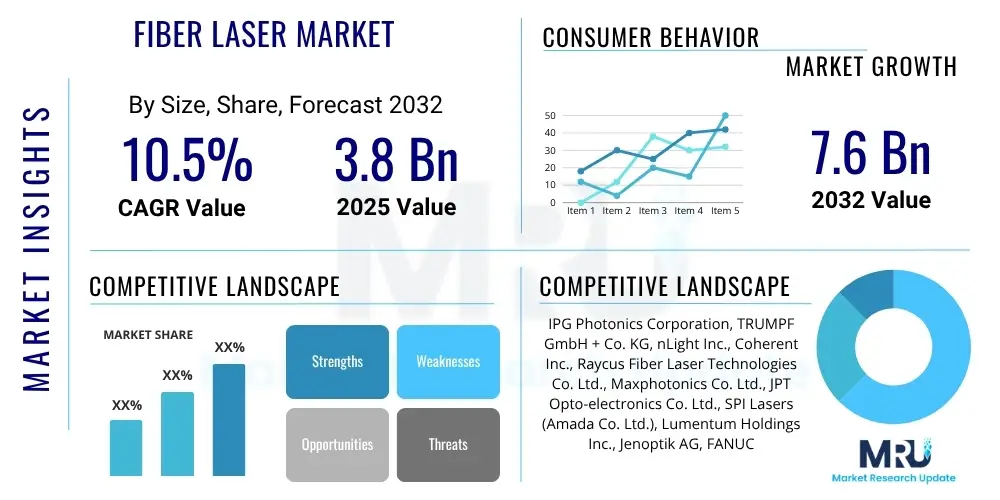

The Fiber Laser Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2025 and 2032. The market is estimated at $3.8 Billion in 2025 and is projected to reach $7.6 Billion by the end of the forecast period in 2032.

Fiber Laser Market introduction

Fiber lasers represent a cutting-edge laser technology where the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, or neodymium. This unique design allows for excellent beam quality, high efficiency, and a compact footprint compared to traditional solid-state and gas lasers. Their inherent stability and robust construction make them ideal for demanding industrial environments, ensuring consistent performance with minimal downtime. The fundamental principle involves pumping the doped fiber with light from semiconductor diodes, which excites the rare-earth ions, leading to laser emission.

The applications for fiber lasers are remarkably diverse and continue to expand across various sectors. Material processing stands as the dominant application, encompassing high-precision cutting, welding, marking, engraving, and drilling of metals and other materials, offering unparalleled speed and accuracy. Beyond industrial manufacturing, fiber lasers are increasingly vital in medical diagnostics, surgery, and aesthetics due to their precision and minimal invasiveness. They also play a crucial role in telecommunications for data transmission and amplification, and in advanced research and development for scientific exploration.

The growing adoption of fiber laser technology is primarily driven by its superior benefits over conventional lasers. These include significantly higher energy efficiency, leading to reduced operational costs, and exceptional beam quality that enables finer processing and higher throughput. Furthermore, their compact size facilitates integration into automated systems and robotic platforms, aligning with Industry 4.0 initiatives. The low maintenance requirements and long operational lifetimes further enhance their appeal, contributing to a lower total cost of ownership for end-users across various industries seeking reliable and high-performance laser solutions.

Fiber Laser Market Executive Summary

The Fiber Laser Market is experiencing robust growth, propelled by the increasing demand for high-precision, high-efficiency, and highly automated manufacturing processes across diverse industries. Business trends indicate a strong focus on technological advancements, particularly in developing higher power fiber lasers, ultrafast pulse lasers, and integrated laser systems that offer enhanced capabilities and ease of use. Key players are investing heavily in research and development to introduce innovative solutions that cater to niche applications while also working towards cost reduction and improved system reliability. Consolidation activities and strategic partnerships are also becoming prevalent as companies seek to expand their market reach and technological portfolios.

From a regional perspective, Asia Pacific continues to dominate the market, primarily driven by the expansive manufacturing sector in China, which heavily adopts fiber lasers for metal processing in automotive, electronics, and heavy machinery industries. North America and Europe also represent significant markets, characterized by advanced industrial applications, strong research and development capabilities, and a growing emphasis on automation and smart factories. These regions are witnessing increased adoption in aerospace, medical, and specialized manufacturing, with a focus on high-value applications requiring extreme precision and intricate designs.

Segmentation trends highlight the strong performance of high-power fiber lasers, particularly those above 1000W, which are indispensable for heavy-duty material processing applications like thick metal cutting and welding. The pulsed fiber laser segment is also demonstrating significant growth due to its application in fine processing, micro-machining, and sensitive material ablation where minimal heat input is crucial. End-use industries such as automotive, aerospace and defense, electronics and semiconductor, and medical and healthcare are consistently the largest consumers, with emerging applications in additive manufacturing and renewable energy presenting new avenues for growth within the forecast period.

AI Impact Analysis on Fiber Laser Market

User inquiries regarding the influence of Artificial Intelligence on the Fiber Laser Market frequently center on how AI can enhance operational efficiency, optimize process parameters, and enable new levels of automation and precision. Common questions revolve around AI's role in predictive maintenance, real-time quality control, adaptive manufacturing, and potentially in accelerating research and development cycles for next-generation fiber laser systems. There is considerable interest in understanding how AI algorithms can interpret complex sensor data to fine-tune laser performance, minimize material waste, and improve overall throughput. While the benefits are clear, concerns often include the complexity of integrating AI systems, data security implications, and the need for skilled personnel to manage and leverage these advanced technologies effectively.

- Enhanced process control and optimization through machine learning algorithms

- Predictive maintenance and diagnostics, reducing downtime and extending equipment lifespan

- Automated fault detection and correction in real-time during laser operations

- Improved beam shaping and quality control using AI-driven feedback loops

- Adaptive manufacturing processes, allowing lasers to adjust to material variations

- Accelerated research and development by simulating new laser designs and applications

- Intelligent process planning and simulation for optimal production workflows

- Advanced analytics for performance monitoring and operational insights

- Integration with robotic systems for fully autonomous laser processing cells

DRO & Impact Forces Of Fiber Laser Market

The Fiber Laser Market is significantly driven by the escalating demand for advanced material processing across various industries. The inherent advantages of fiber lasers, such as high efficiency, superior beam quality, compact size, and minimal maintenance, make them indispensable for applications requiring precision and speed. The automotive, aerospace, and electronics sectors are rapidly adopting fiber lasers for critical tasks like cutting intricate components, precise welding, and marking, driven by the need for lightweight materials, higher production yields, and stringent quality standards. Furthermore, the global trend towards industrial automation and the integration of smart manufacturing technologies provides a strong impetus for fiber laser market growth, as these lasers seamlessly integrate into robotic systems and automated production lines.

Despite the robust growth, the market faces certain restraints that could impede its full potential. The high initial capital investment required for fiber laser systems can be a barrier for small and medium-sized enterprises (SMEs) to adopt this technology, particularly in developing economies. Additionally, the technical complexities associated with operating and maintaining advanced fiber laser systems necessitate a skilled workforce, which is not always readily available, leading to operational challenges. Intense competition from other established laser technologies, though diminishing in some segments, still poses a challenge, particularly where conventional lasers offer a lower entry cost or are sufficient for specific applications.

Significant opportunities exist for the Fiber Laser Market, particularly in emerging applications and technological advancements. The expansion into new domains like additive manufacturing (3D printing), where fiber lasers offer precise energy delivery for metal powders, presents a substantial growth avenue. The medical industry is increasingly utilizing fiber lasers for intricate surgical procedures, diagnostics, and aesthetics, leveraging their precision and minimal invasiveness. Furthermore, ongoing research and development in ultrafast fiber lasers (picosecond and femtosecond) are opening doors for new micro-machining and advanced material processing applications, while the integration of fiber lasers with Industry 4.0 platforms and artificial intelligence promises enhanced efficiency, predictive maintenance, and greater customization capabilities, thus creating new market niches.

Segmentation Analysis

The Fiber Laser Market is comprehensively segmented across various parameters, including product type, power range, application, and end-use industry. This detailed segmentation allows for a granular understanding of market dynamics, identifying specific areas of growth and technological adoption. Each segment exhibits distinct characteristics and growth trajectories, influenced by technological advancements, economic factors, and evolving industrial demands. The market’s segmentation reflects the versatility of fiber laser technology and its ability to cater to a broad spectrum of requirements, from low-power marking to high-power cutting and welding, across a multitude of industrial and scientific fields.

- By Type:

- Single Mode

- Multimode

- By Power:

- Low Power (up to 100W)

- Medium Power (101W-1000W)

- High Power (above 1000W)

- By Application:

- Material Processing

- Cutting

- Welding

- Marking

- Engraving

- Drilling

- Cladding

- Additive Manufacturing (3D Printing)

- Medical

- Telecommunications

- Research and Development

- Others (e.g., Spectroscopy, Sensing)

- Material Processing

- By End-Use Industry:

- Automotive

- Aerospace & Defense

- Electronics & Semiconductor

- Medical & Healthcare

- Heavy Industry

- Jewelry

- Textile

- Tool & Die

- Others

Value Chain Analysis For Fiber Laser Market

The value chain for the Fiber Laser Market begins with the upstream activities centered on the procurement and processing of raw materials and the manufacturing of core components. This stage involves suppliers of rare-earth elements, which are crucial for doping optical fibers, as well as manufacturers specializing in high-purity silica glass for fiber production. Key component providers supply pump diodes, optical components such as lenses, mirrors, and gratings, and beam delivery systems, all of which are essential for constructing a complete fiber laser system. Precision engineering and advanced material science are fundamental to these upstream operations, ensuring the quality and performance of the final laser product.

Moving downstream, the value chain encompasses the integration of these components into complete fiber laser systems by Original Equipment Manufacturers (OEMs) and laser system integrators. These entities design, assemble, test, and package the fiber lasers, often customizing them for specific industrial applications. Further downstream, the distribution channel plays a critical role in reaching the end-users. This involves a network of distributors, value-added resellers, and direct sales teams who market, sell, and provide after-sales support for the fiber laser products. Service providers also form an integral part of the downstream segment, offering installation, maintenance, repair, and training services to ensure optimal performance and longevity of the laser systems for the end-users.

Distribution channels within the Fiber Laser Market can be broadly categorized into direct and indirect routes. Direct sales are often utilized by major manufacturers to cater to large industrial clients, offering bespoke solutions and direct technical support. This approach allows for closer relationships with key customers and a deeper understanding of their specific needs. Indirect channels, on the other hand, involve a network of independent distributors and integrators who serve a wider range of smaller and medium-sized enterprises (SMEs) across various regions. These partners often provide localized support, technical expertise, and integration services, acting as crucial intermediaries in extending market reach and ensuring widespread adoption of fiber laser technology.

Fiber Laser Market Potential Customers

Potential customers for fiber laser products are diverse, spanning a wide array of industries that benefit from the technology's precision, efficiency, and versatility in material processing and other advanced applications. These end-users are typically organizations that require high-quality, repeatable, and cost-effective solutions for tasks such as cutting, welding, marking, or specialized medical and telecommunications applications. The continuous innovation in fiber laser capabilities, including higher power outputs and ultrafast pulse durations, expands their applicability to new materials and more complex processes, thereby broadening the customer base significantly.

The primary buyers of fiber lasers include large-scale manufacturing enterprises, small and medium-sized fabrication shops, research institutions, and specialized service providers. For manufacturers, fiber lasers offer a competitive edge through improved throughput, reduced scrap, and lower operational costs. Medical and healthcare facilities utilize these lasers for advanced diagnostics and therapeutic procedures, while telecommunication companies rely on them for robust data transmission. The appeal of fiber lasers lies in their ability to deliver consistent, high-performance results across a spectrum of industrial and scientific requirements, driving their adoption across a global customer base.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.8 Billion |

| Market Forecast in 2032 | $7.6 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IPG Photonics Corporation, TRUMPF GmbH + Co. KG, nLight Inc., Coherent Inc., Raycus Fiber Laser Technologies Co. Ltd., Maxphotonics Co. Ltd., JPT Opto-electronics Co. Ltd., SPI Lasers (Amada Co. Ltd.), Lumentum Holdings Inc., Jenoptik AG, FANUC Corporation, CY Laser S.r.l., Wuhan Golden Laser Co. Ltd., Han's Laser Technology Industry Group Co. Ltd., EKSPLA, AdValue Photonics, Toptica Photonics, Menlo Systems GmbH, Novanta Inc., Universal Laser Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Fiber Laser Market Key Technology Landscape

The technological landscape of the Fiber Laser Market is characterized by continuous innovation aimed at enhancing performance, efficiency, and versatility. Core to this landscape is the advancement in double-clad optical fibers, which allow for efficient pumping of rare-earth doped cores, facilitating high power output while maintaining excellent beam quality. Significant progress has also been made in semiconductor pump diode technology, leading to more powerful, efficient, and reliable pump sources that are critical for achieving higher laser output powers and extending the operational lifetime of fiber laser systems. The development of specialized fiber gratings and couplers further optimizes the internal optical architecture, contributing to stable and precise laser emission.

Further advancements are seen in the development of ultrafast fiber lasers, including picosecond and femtosecond pulse durations. These technologies are crucial for cold ablation processes, enabling precise material removal with minimal heat affected zones, which is vital for micro-machining of sensitive materials in industries like electronics, medical device manufacturing, and display production. Wavelength diversity is another key trend, with innovations expanding the range of available wavelengths, allowing fiber lasers to be tailored for specific material absorption characteristics and application requirements. This includes developments in green, UV, and mid-infrared fiber lasers, opening up new processing opportunities for traditionally challenging materials.

The integration of sophisticated control systems and beam delivery technologies also defines the modern fiber laser landscape. Advanced optical heads with adaptive optics and remote processing capabilities allow for greater flexibility and automation in manufacturing environments. Smart monitoring systems that track laser performance, beam parameters, and operational diagnostics in real-time are becoming standard, enhancing reliability and enabling predictive maintenance. These technological strides collectively contribute to fiber lasers being at the forefront of advanced manufacturing and scientific research, continuously pushing the boundaries of what is possible in precision processing.

Regional Highlights

The global Fiber Laser Market exhibits diverse growth patterns and adoption rates across different geographical regions, largely influenced by industrialization levels, technological advancements, and economic development. Each region contributes uniquely to the market's overall trajectory, with some serving as established hubs for innovation and manufacturing, while others emerge as significant growth frontiers due to rapid industrial expansion.

- North America: This region is a significant market driven by strong investments in advanced manufacturing, aerospace and defense, and medical device industries. The presence of leading research institutions and a high adoption rate of automation technologies contribute to its market growth.

- Europe: Characterized by a robust industrial base, particularly in Germany and Italy, Europe is a key player in the fiber laser market. The automotive sector, precision engineering, and a focus on Industry 4.0 initiatives are major drivers for adoption.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for fiber lasers, predominantly fueled by China's extensive manufacturing capabilities across electronics, automotive, and heavy industries. Emerging economies like India, South Korea, and Japan also contribute significantly with their growing industrial and technological landscapes.

- Latin America: While a smaller market compared to others, Latin America shows promising growth, particularly in the automotive and metal fabrication sectors in countries like Brazil and Mexico, as industries seek to modernize their production processes.

- Middle East and Africa (MEA): This region is experiencing nascent but growing adoption of fiber lasers, driven by ongoing infrastructure development projects, diversification efforts in manufacturing, and increasing investments in technology-driven industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Fiber Laser Market.- IPG Photonics Corporation

- TRUMPF GmbH + Co. KG

- nLight Inc.

- Coherent Inc.

- Raycus Fiber Laser Technologies Co. Ltd.

- Maxphotonics Co. Ltd.

- JPT Opto-electronics Co. Ltd.

- SPI Lasers (Amada Co. Ltd.)

- Lumentum Holdings Inc.

- Jenoptik AG

- FANUC Corporation

- CY Laser S.r.l.

- Wuhan Golden Laser Co. Ltd.

- Han's Laser Technology Industry Group Co. Ltd.

- EKSPLA

- AdValue Photonics

- Toptica Photonics

- Menlo Systems GmbH

- Novanta Inc.

- Universal Laser Systems Inc.

Frequently Asked Questions

What is a fiber laser and how does it work?

A fiber laser is a type of laser where the active gain medium is an optical fiber doped with rare-earth elements like ytterbium. It works by pumping light from semiconductor diodes into the doped fiber, exciting the rare-earth ions, which then emit photons and amplify light, producing a high-quality laser beam. This design ensures high efficiency and excellent beam characteristics.

What are the primary applications of fiber lasers?

Fiber lasers are primarily used in material processing for precise cutting, welding, marking, and engraving of various materials, especially metals. Other significant applications include medical diagnostics and surgery, telecommunications for data transmission, and a wide range of scientific research and development activities.

How do fiber lasers benefit industrial manufacturing?

Fiber lasers offer numerous benefits to industrial manufacturing, including superior energy efficiency, high-speed processing, exceptional beam quality for fine detailing, and a compact, maintenance-free design. They enable increased production throughput, reduced operational costs, and enhanced precision in complex manufacturing tasks, supporting automation and Industry 4.0 initiatives.

What are the main types of fiber lasers available in the market?

Fiber lasers are categorized by their output power (low, medium, high power) and mode type (single mode, multimode). They are also distinguished by their pulse duration (continuous wave, pulsed, picosecond, femtosecond), which dictates their suitability for various applications, from heavy-duty cutting to delicate micro-machining.

What is the future outlook for the fiber laser market?

The future outlook for the fiber laser market is highly positive, driven by continued technological advancements leading to higher power outputs and new wavelengths. Opportunities in additive manufacturing, medical applications, and the increasing integration with artificial intelligence and industrial automation are expected to fuel substantial growth. Market expansion into emerging economies will further boost demand.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Fiber Laser Cutting Machines Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- High-Power Infrared Fiber Laser Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Fiber Laser Cutter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Quasi CW Fiber Laser Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Fiber Laser Drilling Machine for Automotive Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager